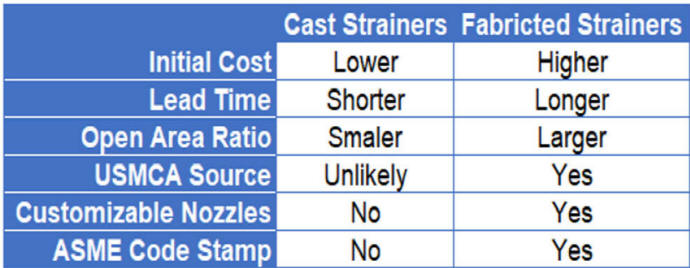

Comparison of Fabricated and Cast Strainers

Which do you need - a cast or fabricated basket strainer design?

Pipeline strainers are often considered a commodity product because the primary design criteria are considered “universal”:

PRIMARY DESIGN CRITERIA

1.

material of construction

2. connection type

3. connection size

4.

style simplex, duplex or automatic

5. element retention

This article explains the differences of cast and custom fabricated strainer designs, complementing the following articles:

-

How to Compare and Select Cast Simplex Strainers, Avoid the pitfalls related to relying on only size and cost

-

How to Select a Pipeline Strainer, Three design criteria for proper strainer selection

-

Effects of Fluid Velocity and Differential Pressure on Pipeline Strainers, Considerations for proper strainer sizing

Simply put, most customers use fabricated strainers

to maximize filtration efficiency for their specific application. Sometimes

the liquid characteristics or engineering specifications necessitate using a

custom fabricated design, but you can benefit from using a custom fabricated

strainer design even when a cast design would work.

Open Area Ratio

Cast strainer

designs have a fixed open area ratio (OAR); this is the ratio of the open

area of the filter element to the open area of the inlet nozzle. As this

ratio increases the frequency of element cleaning decreases. The OAR is

mostly dictated by the strainer design, with Y and T styles having low

ratios (1:1 or 2:1) and basket strainers of 5:1 or better OARs.

Although it is not a guarantee, most fabricated strainers have a higher OAR

than cast strainers and that is because cast strainers are designed to

minimize cost. It is possible to cast strainers with thinner wall

thicknesses and overall smaller dimensions compared to their fabricated

versions which are physically larger due to the required welding procedures.

OAR

Trade-Off

OAR

Trade-Off

You might enjoy an initial cost savings and

quicker delivery purchasing a cast strainer at the expense of more frequent

basket cleanings. Labor hours related to strainer maintenance are often

overlooked during the procurement process, but it should not because pipeline strainers

last decades and those labor hours add-up over the years. Its not only labor

hours, personnel exposure to the process liquid and spillage contribute to

overhead costs also.

Applications Requiring Fabricated

Strainers

Some applications require features which cannot be

provided in cast designs, for example allowing for corrosion. Due to the

manufacturing technique for cast strainers it is not possible to customize

the thickness of the body or nozzles. Such strainers have varying wall

thicknesses with the design meant to withstand a certain pressure and

temperature combination and cannot be altered from the tooling used at the

foundry.

Fabricated strainers can be made from thicker materials,

their connections can be customized by size, type and location and they are

available in exotic alloys that cast versions are not.

Examples of Customized Fabricated Strainers

One of the most common customizations differentiating fabricated strainers

from cast strainers is attaching smaller sized connections to match the

pipeline it will be installed into; this is done to improve the OAR.

Liquid can be transferred at high velocities and therefore smaller pipeline

sizes are used to reduce cost and space but this can be problematic for a

pipeline strainer. Once the inlet velocity exceeds about 10 FPS there is an

increased likelihood that the internal strainer basket is damaged. Strainer

baskets are typically sealed against the strainer body through the downwards

force the cover applies to the arched spring-like basket handle. At high

velocities the baskets begin to spin, damaging both the basket and strainer

body.

In such situations the strainer body can be

oversized, so perhaps you are essentially installing a 6" strainer into a

4" pipeline. A 6" fabricated strainer can have 4" connections, doubling the

OAR from 7:1 to 14:1 and reducing the velocity by almost 50%. If a cast 6"

strainer was used, a separate transition spool would need to be fabricated

for the inlet and outlet, increasing the overall cost and number of

potential leakage points.

Mesh lined baskets reduce the OAR of a given size

strainer significantly unless offset by using a larger size basket

commensurate with a larger sized

strainer body.

Code Stamps, NDT and NDE

Only

fabricated strainers can be provided with an ASME code stamp due to the

specific manufacturing requirements related to code stamping. Applications

requiring magnetic particle testing, ultrasonic weld/wall thickness tests

and non-standard welding procedures (or even a requirement of minimum welder

qualifications) are indications that a fabricated strainer is required.

These types of requirements are often industry specific with the oil and gas

industry being notorious for ensuring stringent manufacturing and quality

control procedures are used throughout the manufacturing process.

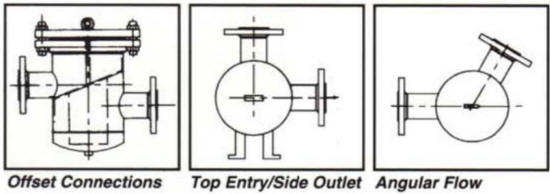

Alternate Nozzle Locations

The basic pipeline strainer

design has inlet and outlet nozzles 180° apart at the same elevation, often

referred to as "inline". This is the most common nozzle orientation, however

there are applications which benefit from nozzles having the inlet and

outlet on the same side (referred to as "loop" configuration) and even 45°

or 90° offset. Most of the time these special nozzle

orientations are driven by limited space as might be characteristic of

portable systems located on trucks and ships.

Advantages of Cast Strainers

If your flow rate (velocity) and OAR can be satisfied with a cast strainer

then you benefit from lower costs and quicker lead times. Cast strainers are

mass produced and require less labor; the labor that is used is often

low-cost labor because most cast strainers originate from foundries in China

and India. These countries do not have the environmental and labor

protection laws that manufacturers in the USA are subject to, so it's just

not possible to cast strainers in the USA at a competitive price.

As

previously mentioned, the amount of material used for a cast product is

often less due to sophisticated tooling used by the foundry, a big factor

contributing to lower cost. So even after you account for the ocean freight

cost to North America, cast strainers almost always cost less than a locally

fabricated strainer.

Yoke Style Access Covers

Most cast strainers have quick-opening strainer basket chamber covers which require only a few turns of a T-Bolt to access the strainer basket. Fabricated designs typically have a fully bolted cover design with an option for a hinged cover and swing-bolts which add significantly to the cost of the strainer due to the extra labor.

Quick Delivery

The mass

production nature of cast strainers results in physical inventory and lead

times reduced to whatever is required to fabricate the strainer basket

(typically within 1 week). Fabricated strainers must go through a rigorous

process of drawing generation/approval, acquiring raw materials,

cutting/bending and welding procedures in addition to various

non-destructive testing (NDT), resulting in at least 4 to 6 weeks for

shipment after receipt of an order. If there are supply chain interruptions

or a backlog of orders that lead time can easily extend to 12+ weeks.

Made

In the USA

Made

In the USA

There are increasing requirements for government

agencies and their vendors to purchase products of which 55% of their value

originates from the USA. It is difficult to supply a cast strainer for such

applications because the strainer body itself is often cast overseas. One

way around this (prior to the January 2021 update), was to re-source the

chamber cover hardware (bolts/nuts), fabricating the basket, re-testing

(hydrostatic test) the body and re-painting the strainer so it can be

considered to have enough USA value to satisfy the Buy American Act

requirements. These added parts and procedures increased the cost and lead

time, reducing the biggest advantages of cast strainers. Now that they Buy

American Act has been updatcASTed, 95% of the iron and steel content must be

of US origin to satisfy the Buy American Act. An exception can be made if

the foreign cast strainer is 20-30% less expensive than the USA version.

Let us leverage our strainer sizing and selection experience

from the previous 20 years to assist you with your next strainer

application. We approach your project from the perspective of solving a

problem or satisfying specific goals; explaining and quoting multiple

options to ensure you are making an informed decision. Our website at

https://fdpp.com has many articles, PDF files

and automated sizing tools enabling comparison of several brands of

strainers; our assistance is only a phone call or email away and has no cost

or obligation to you.