Anatomy of a Pressure Gauge

How a bourdon pressure gauge works

Pressure gauges are

commonplace and used to indicate the pressure of a pipeline, but do you know

how they work and why there seems to be large differences in pricing for

what appears to the same product?

The importance of a

pressure gauge is often overlooked. A well-designed and properly sized

pressure gauge should provide accurate service for years. The

performance of spray nozzles, pumps and other fluid components are evaluated

by pressure gauges in the fluid system. A quality pressure gauge will

pay for itself by increasing the accuracy and control of your process.

Since the Bourdon

tube style is the most commonly used design, this article will focus on

Eugene Bourdon's invention over 175 years ago.

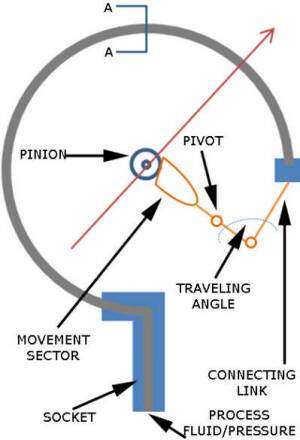

The basic operating

principle of a Bourdon tube gauge is a hollow, C-shaped tube which is opened

to pressure at one end and welded shut at the other. When the tube is

pressurized it tries to straighten-out, moving attached linkage and a

pointer to indicate the precise pressure. The design of the Bourdon

tube, having a curvature and thus the inside radius being less than the

outside radius makes it possible to correlate the movement of the tube to a

specific pressure.

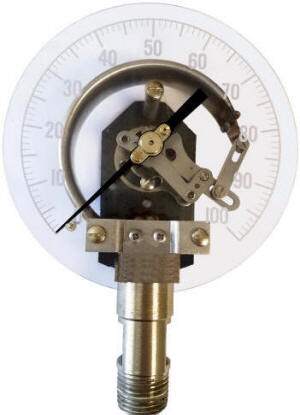

Peel-off the case to see what is inside!

Actually, starting

with the case is a good beginning. The outer case of a gauge is

typically made from plastic, painted or plated steel, brass or - most

commonly - stainless steel. Some cases are designed to be opened for

servicing the gauge, but most are not, so you never get to see what is

inside. The complexity of the case is the first indication of cost; a

case designed to allow a glycerin/silicon fill needs to seal to prevent

leakage and thus is slightly more complex/expensive than a "dry" gauge that

is not "fillable". Likewise, some gauge cases are made with a solid

front so in the event of a catastrophic internal failure the process fluid

is directed backwards and presumably away from personnel. Finally,

cases can be designed for mounting within panels or simply mounted to the

fluid system.

The

pressure gauge socket (inlet) is the first part of the gauge the process

fluid contacts, unless you are isolating it with a diaphragm seal.

Inexpensive gauges simply have a hole drilled into the inlet connection,

more expensive gauges have a threaded hole, in which can be installed a

restrictor orifice. A removable restrictor orifice provides two basic

functions, slight dampening of the inlet surge and protecting the internals

of the gauge from particles that can become embedded within the Bourdon

tube, causing it to malfunction. If some foreign material becomes

caught on the orifice, it can easily be removed, however once material

becomes lodged within the Bourdon tube the likelihood of removing it is

slim.

The

pressure gauge socket (inlet) is the first part of the gauge the process

fluid contacts, unless you are isolating it with a diaphragm seal.

Inexpensive gauges simply have a hole drilled into the inlet connection,

more expensive gauges have a threaded hole, in which can be installed a

restrictor orifice. A removable restrictor orifice provides two basic

functions, slight dampening of the inlet surge and protecting the internals

of the gauge from particles that can become embedded within the Bourdon

tube, causing it to malfunction. If some foreign material becomes

caught on the orifice, it can easily be removed, however once material

becomes lodged within the Bourdon tube the likelihood of removing it is

slim.

The body of the

socket and especially how the Bourdon tube is welded to the socket is

critical to a long-lasting pressure gauge; you want quality materials and

quality welding.

Welding

style and quality equally applies at the closed end of the Bourdon tube,

where the linkage is attached. A pivot point to which a geared

movement is attached is connected to the linkage on the other side, thus as

the Bourdon tube "flexes", the angle of the linkage moves the geared

movement.

Welding

style and quality equally applies at the closed end of the Bourdon tube,

where the linkage is attached. A pivot point to which a geared

movement is attached is connected to the linkage on the other side, thus as

the Bourdon tube "flexes", the angle of the linkage moves the geared

movement.

These internals are

protected from moisture or an aggressive environment when the gauge is

filled with glycerin or silicon. The gauge quality and its cost are a

reflection of these internal components. For example, machined

components are often of higher quality and have more "endurance" than less

expensive stamped components because they need to be thicker to machine.

The geared movement rotates the pointer to the corresponding scale on the

gauge dial (face), thus finer gears equate to increased accuracy. The

materials used are also an indication of quality; stainless steel components

will often outlast copper alloy parts.

The pointers

themselves vary in complexity. Some like the one picture here enable fine

adjustments to compensate for altitude or wear caused by pulsations and

vibration.

![]()

![]()

Pointers can also

trigger separate high and low pressure pointers affixed to the gauge window

to record extreme conditions when incorporating a pressure transducer is not

possible.

The pressure gauge

dial has a scale that is calibrated to the Bourdon tube, if you want, the

dial can be customized with a company name, logo or colors - such gauges

incur an artwork charge and have 10+ weeks lead-time associated with them.

Pressure

Gauge Accuracy

Pressure

Gauge Accuracy

You will often see

the accuracy of a pressure gauge expressed as "3-2-3% ASME B40.1 Grade B" or

"2-1-2% ASME B40.1 Grade A" and this refers to the accuracy for each third

of the dial scale. Therefore, the 1st and 3rd

sections of the dial are the least accurate and the middle portion of the

gauge is most accurate. When selecting a pressure gauge try to choose

a scale such that your normal operating pressure will fall within the middle

portion of the range to maximize accuracy. Some gauges offer

accuracies of 1% of full scale (FS) which means it is 1% accurate anywhere

on the dial.

The last piece of a

gauge is its window, which protects the pointer and gauge internals from

the surrounding environment. A gauge window can be made of glass, tempered

glass and hard or soft plastic. Soft plastic windows are often

referred to as thermal compensating because they flex, allowing for

glycerin/silicon fill to expand without bleeding from the gauge case.

This is also why filled gauges usually have an air bubble towards the top,

allowing for expansion due to heat or altitude.

With an understanding

of how a Bourdon tube gauge works, the components involved and accuracy you

are empowered to select the most appropriate pressure gauge for your product

or application.