Cast Bronze Steel Y Strainers

Inexpensive wye strainers for seawater, water and steam

Our cast bronze steel Y strainers are for ¼" to 12" size pipelines. Keckley offers the broadest selection of bronze Y strainers. Titan is limited to threaded and solder end connection to 3" sizes whereas Keckley also offers ANSI flanged versions. Eaton acquired their bronze Y strainer product line from Hayward in 2005, subsequently selling it to Titan.

Y strainers are designed to protect equipment downstream from particulate. The distinction is that the larger open area ratio of basket strainers are designed for continuous removal of particulates. Please refer to our article SIMPLEX STRAINERS: Differences between Y and Basket Style Strainers for additional information.

You can attach a manual or automated valve to the drain port of Y strainers to enable "blow down" of material retained within the element. The effectiveness of this "cleaning" depends upon the nature of the retained particulate and whether they are embedded within the screen itself. Therefore such blow-down type applications are best suited for relatively few particles which are hard in nature.

The blow-down aspect of Y strainers was intended for use with steam systems and removal of pipe scale, however some customers do use this approach with water and other fluids with some degree of success.

We do offer a "flushing" version of our simplex strainers; you can learn more about these at our Flushing Strainers Webpage. Our flushing basket strainers combine the larger open area ratio of a basket strainer with flushing capability of a Y strainer to reduce the frequency of physical cleaning required.

Keckley's bronze Y strainers have a significantly higher flow coefficient (Cv) value compared to Titan with exception to the 3" size for which they are the same.

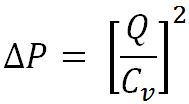

The Cv value is a representation of how much flow is restricted, thus a higher Cv equates to a lower differential pressure for a given flow rate; another way of stating this is that a higher Cv will allow for higher flow at a given differential pressure. The formulas for each follow:

Use the following formula to compare the initial clean differential pressure of strainer models using their Cv values:

(Q = Flow rate in GPM, ΔP = calculated differential pressure)

To compare the maximum flow rate (capacity) between strainer models use the following formula:

(ΔP = your maximum acceptable clean differential pressure; industry standard = 2 PSIG)

How important is the Cv value for your application? If your application involves protecting the suction side of a pump or blower system, it probably makes a difference. This is why we encourage customers to your our application based Y strainer inquiry form, so we can suggest the most appropriate model based upon the design criteria for your specific application.

It is not prudent to simply select a Y strainer based only on cost, assuming that since it has the same connection size it will perform the same as other designs. Generally speaking, finer retentions and sensitivity to differential pressure requires comparison of the flow coefficient values.

Please note that there are two interactive differential pressure calculators covering three Keckley cast bronze Y strainer models. Notice that some Y strainers, although having the same connection size, have a higher or lower clean differential pressure value. This is a reflection of their Cv value (particular design) and underscores that "not all like size strainers are equivalent".

You can calculate the approximate clean differential pressure drop by selecting the strainer connection size, inputting your flow rate (GPM), inputting the specific gravity if other than water (sg of water = 1) and select the viscosity range if other than water (SSU of water = 30). Click "Update" to refresh the data and be sure that the clean differential is ≤2 PSI for the intended basket retention.

Please feel free to contact us via phone or email with assistance in selecting the best Y strainer for your application. At that time we can also confirm availability and pricing based upon the screen size desired.

| Catalog Pages with IOM Manual and Outline Drawings |

| Keckley Y Strainers |

| Titan Y Strainers |