How to Compare and Select Cast Simplex Strainers

Avoid the pitfalls related to relying on only size and cost

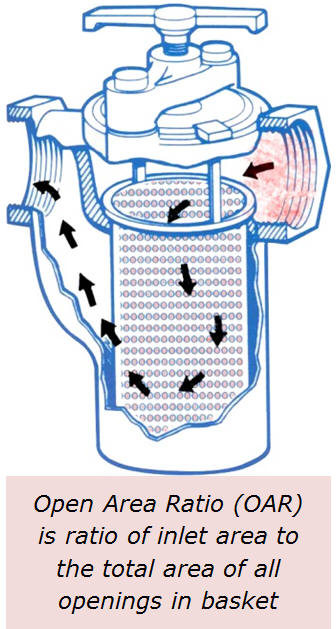

Cast and molded simplex strainers have a fixed ratio of cross-sectional inlet opening to basket-surface area whereas custom fabricated simplex basket strainers can be designed for higher straining ratios. The open area ratio (OAR) takes into account the open area of the basket for which the fluid passes through with mesh lined baskets having less open area than perforated baskets. You can use the OAR to quickly identify strainer designs which might require less frequent basket cleaning.

Cast strainers are mass-produced in foundries located in other countries

where environmental regulations are less stringent and both material and

labor costs are minimal, causing them to be significantly less expensive

than custom fabricated basket strainers. Often cast simplex basket

strainers weigh 80% or less than comparable fabricated simplex basket

strainers because the molds used by foundries enable thinner wall

thicknesses; this characteristic also reduces material cost and is an

advantageous feature when installed on portable equipment.

Foundry tooling for cast strainers is expensive to design, maintain and

modify which is why fabricated strainers are used when custom nozzle

orientations, additional ports/connections, a thicker walled design,

higher straining ratios or other such customizations are required.

Cast Simplex Basket Strainer Designs:

Internal Geometry and Ergonomic Features

When a cast strainer is appropriate for an application it is commonplace to simply search for a strainer size equal to the pipeline it will be installed, matching the strainer material to that of the pipeline; often cost and availability become the primary selection criteria. Have you ever wondered "Why is there such a variation in cast simplex basket strainer pricing for a given size and material?"

Several Aspects to Compare Before Deciding

The basket design is a process related aspect to consider because it directly

relates to the efficiency of the strainer design.

Some strainer baskets have a slanted entrance ring

and others are tubular with flow passing over the "top"; whether there

is an advantage to either style is application specific. If your

pipeline velocity and particle load is low or your fluid is shear

sensitive, a slanted basket design might offer better performance.

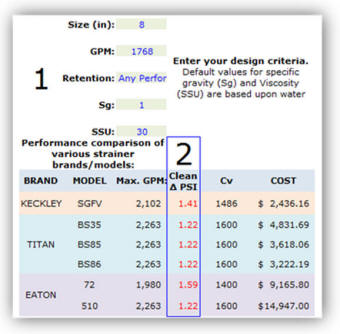

The design of a cast simplex strainer dictates the design of the strainer

basket. You can compare simplex basket strainer designs without comparing

the surface areas of baskets by referring to the strainers flow coefficient

value (Cv).

Just because "model A" has a Cv value higher than

"model B" does not necessarily

mean it will perform better. While a larger strainer basket is associated

with a higher Cv value and can retain more material before requiring cleaning,

much depends upon your flow rate and particle load.

![]()

If your flow rate is low for the pipeline size (a fluid velocity

<= 5 FPS) the

difference in flow resistance will likely be negligible. Likewise, if

strainer baskets are cleaned based upon schedule and not only at high

differential pressures, a design with a lower Cv would be functionally

acceptable.

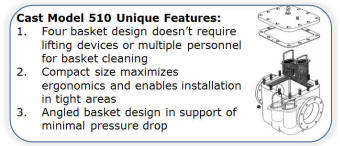

As an example, the 510 has a special low-to-the-floor, multi-basket design. Its straining ratio is the highest of all the strainers listed and the multi-basket design eliminates the need for overhead lifting devices. If you are only shopping for the lowest cost, you might not even realize that such a design exists!

Strainer chamber covers can be secured to the strainer body with studs/nuts or a

"quick opening" style that does not require tools to open the basket chamber,

such as a yoke style clamp, swing bolts or knobs.

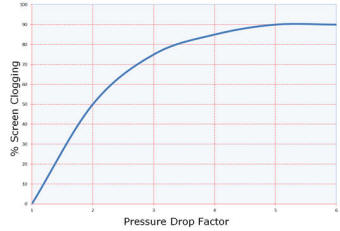

A pair of pressure

gauges or an actual differential pressure gauge (available with switches

and transmitters), measures the differential pressure across the

strainer basket as an indication of clogging. If the differential

pressure exceeds 15 to 20 PSIG there is increased likelihood of strainer

basket damage. Ideally you want to clean the basket after the

differential pressure increases by 5 PSIG above the initial "clean"

differential pressure, which would indicate up to a 75-80% clogged

basket.

There are many factors that to consider prior to selecting a simplex basket strainer that are not easily discerned with online searches based solely on size or price. Our company has nearly 30 years of experience and training in the application of pipeline strainers enabling us to provide valuable advice in support of choosing the best strainer design for your specific application.

Once we have settled on the "best" strainer design for your specific application

we can assist with providing the accessories you might need such as differential

pressure gauges with or without switches and vent/drain/isolation valves that

are compatible with your process.