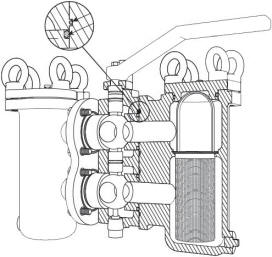

Titan Model DS Duplex Strainers

Cast threaded and flanged duplex strainers

Titan cast duplex basket strainers use a cleverly designed flanged diverting valve to divert flow from one strainer basket chamber to the other. This design provides a bubble tight seal, similar to the Eaton model 53BTX, however it is much easier to rebuild due to this flanged body design.

There is very little torque required to divert the flow from one chamber to the other and no tools are required to access the strainer basket chambers. The handle is positioned over the chamber in service. To safely access the isolated basket chamber, open the vent valve or plug, then open the drain or drain plug. Once the fluid has drained from the chamber you can safely open it to clean or replace the strainer basket.

Unlike Eaton model 53BTX and Keckley DPX duplex strainers, Titan offers their duplex basket strainers in both 150# and 300# designs, thus Titan can satisfy high pressure duplex strainer requirements with a cast design, minimizing cost and lead time. Custom fabricated duplex strainers for high pressures generally cost more, have longer lead times and are physically larger.

Navigate to the desired material of construction to calculate the clean differential pressure drop for your specific application; there are catalog and drawing links by strainer model at the bottom of each page.

Titan duplex strainer catalog pages and drawings