Y Strainer Design

Y Strainers and their Applications

The

lowly Y strainer, unsung hero of industrial filtration! This article

describes alloy and non-alloy Y strainer designs, typical applications

they are used for and considerations for determining if a T or basket

strainer would be a better choice for your application. Our

articles

How

to Choose Between a Y and Tee Strainer? and Differences

between Y and Basket Strainers provide in-depth

comparisons.

The

lowly Y strainer, unsung hero of industrial filtration! This article

describes alloy and non-alloy Y strainer designs, typical applications

they are used for and considerations for determining if a T or basket

strainer would be a better choice for your application. Our

articles

How

to Choose Between a Y and Tee Strainer? and Differences

between Y and Basket Strainers provide in-depth

comparisons.

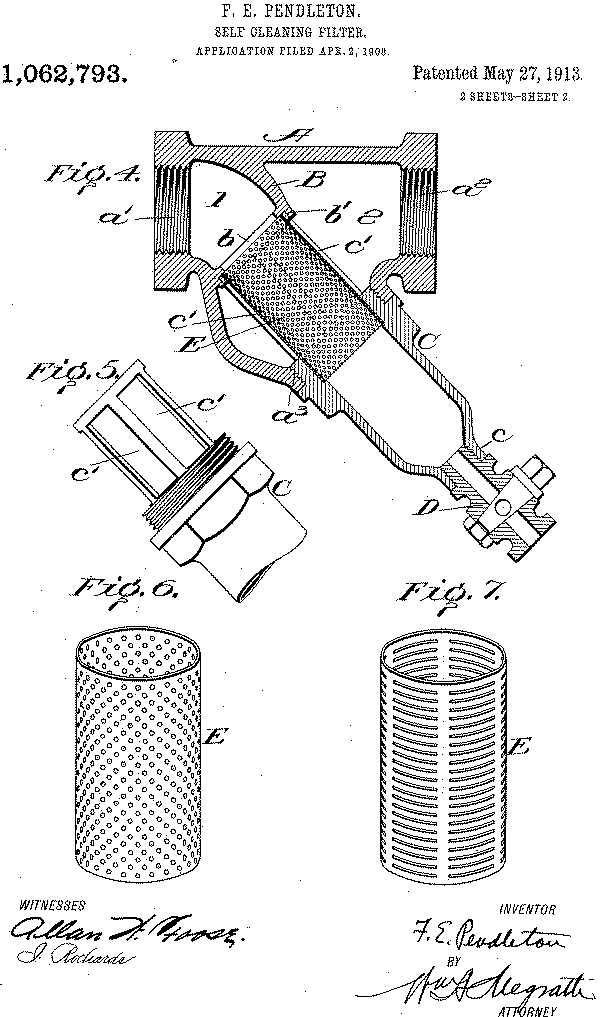

Mr. Frank Pendleton of Montclair New Jersey seems to be the inventor of the Y strainer, applying for a patent in 1908. At the time it was designed to separate sand, gravel and other solid material from water passing through a pipe, however he noted that this design also had applications involving liquids and gasses.

Unlike T and basket strainers, material accumulated within Y strainers can be purged through a valve attached to the element chamber.

There have been some improvements to the original design; in 1953 The Henry Valve Company patented a design where one end of the Y strainer element was angled in support of a higher flow coefficient (Cv) and thus reduced differential pressure.

Fluid enters a Y strainer and passes through a cylindrical element separating debris at a level determined by the openings within the element. The separated material resides within the element chamber until it is removed for cleaning. Alternately a valve is attached to the element cover and when opened the trapped material is quickly flushed from the chamber due to the differential pressure of the process fluid and atmospheric pressure.

Y strainers may also be installed in vertical sections of piping as long as the flow is downwards, because otherwise separated particulate would not reside in the element.

As illustrated on this page, most Y strainers are a cast design made of iron, steel, bronze or 316SS but they can be cast in any foundry castable material. Y strainers are also offered in molded and fabricated designs. Fabricated Y strainers are very similar to T strainers and the T shape is easier to fabricate although sometimes the Y shape enables a larger open area straining ratio. Likewise, there are materials such as FRP and PTFE which do not lend themselves to molding and so when special materials are required fabrication is a possibility.

Importance of Open Area Ratio

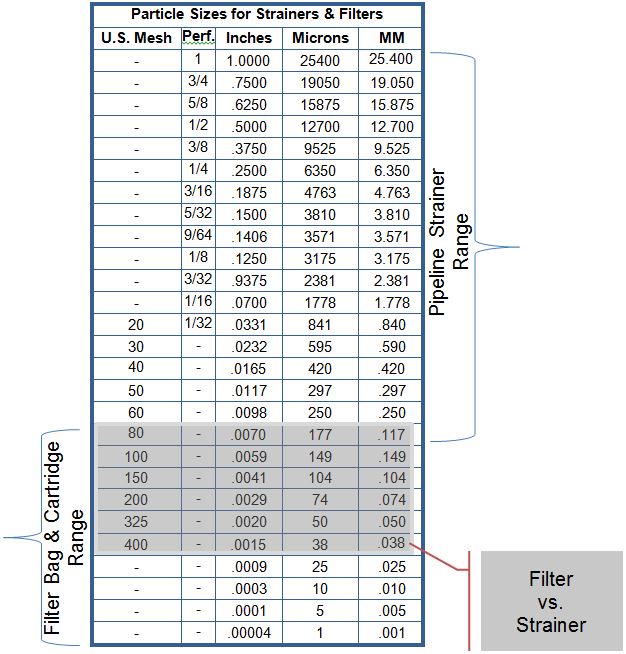

The comparison of the pipeline area to the "free area" (openings in the strainer element) is referred to as the open area ratio (OAR).

Example: A 4" pipe has a 12.73" nominal open area and the element used in 4" Eaton model 85 Y strainers has a free screen area of 38.4" and therefore it has a 3:1 OAR.

Larger OARs are indicative of larger elements and thus require less frequent blow-down or cleaning than strainers with lower OARs. As originally conceived by Mr. Pendleton, a trap or elongation of the element chamber may increase duration between clean-outs without an increase in the OAR.

If you are comparing Y strainer brands and models, begin with comparing their Cv values because that reflects the design of the strainer in its entirety. Realize that less expensive Y strainers might have a lower OAR and Cv value even though they have the same inlet and outlet size; that is because shortening the element chamber (and element) reduces the amount of material required for the strainer - minimizing cost at the expense of performance.

Applications for Y Strainers

Whereas basket strainers typically have OARs of up to 8:1, Y strainers tend to have OARs in the 3:1 range, leading us to the first criteria to selecting a Y strainer - amount of particulate to remove.

Y strainers are best suited for applications which have few particulates to remove, such debris as pipe scale or from an upset condition. Y strainers are not designed to continuously separate particulate as the frequency of element cleaning increases with the particle load.

Besides their compact shape, the best feature of a Y strainer is the ability to purge the element chamber without shutting down the process flow; purging can even be automated with a ball valve and actuator. However, since the purging is akin to "flushing", hard, non-deformable materials are most efficiently purged. Organics which might deform and extrude within the element openings will likely require physical cleaning.

Applications involving physically hard materials benefit most from the blow-down design inherent of Y strainers.

Y strainers are most efficient when removing coarse debris and not as efficient for fine levels of filtration. While there are some Y strainer designs having a gasket sealed element, the most common design is a metal-to-metal sealing of both ends of the cylindrical element. Sometimes the ends of the element are re-enforced and other times they aren't. The design of a Y strainer is such that the interface of the element and strainer body is not significantly precise. Exceptions would include molded custom and fabricated designs, but generally once you get finer than 80 or 100 mesh you would have better results with a basket style strainer.

Cast, Molded and Fabricated Designs

Custom fabricated Y strainers are only used when there are special requirements necessitating the corresponding expense and additional lead times associated with custom fabrication. As an example, if you require an ASME code stamp or have a vertical downwards application in need of a higher than usual OAR, a fabricated Y strainer may be your only choice. PTFE, PVDF, FRP and exotic alloys used for aggressive fluids would also result in a fabricated Y strainer design.

Where pressure and temperature permits, molded Y strainers offer some advantages not found in alloy designs such as gasket sealed elements, true-union pipe connections and quick-opening element covers. PVC and CPVC Y strainers cost more than cast iron designs, but significantly less than cast steel and stainless steel Y strainers. Molded Y strainers have limitations; they are incompatible with compressed gasses, materials such as PVC and CPVC become brittle at temperatures <40F, and its generally not recommended to install plastic strainers or valves within alloy piping. The non-alloy designs are limited in size, usually they are for pipelines sizes up to 4".

Cast Y strainers are typically stocked in

iron, steel, bronze and stainless steel in sizes up to 12", available in

threaded/flanged/butt-weld/ring-joint and socket connections as well in pressure

classes from 125# to over 2500#. Cast Y strainers have the most options,

relegating molded Y strainers and fabricated Y strainers to applications having

"special circumstances".

Remember we are here to assist you! Please contact us by phone, email or web-based inquiry form so we can put our experience to work for you!Visit us at https://fdpp.com and let us know how we can assist you with your filtration application!