Patented Integrated Water Filtration and Disinfection System

Revolutionary Non-Chemical Water Treatment for Cooling Towers and Industrial Applications

US (PTO) Patent # 1052622

Authored by Dr. Emmanuel G. Moya/Fluidyne

International, for Green Crown Water and Power Systems

Introducing

Fluidyne International's patented integrated solution for continuous

water filtration and disinfection, preventing scale formation,

inhibiting bacteria, corrosion, and biofilm growth while conserving

water and reducing power consumption. This scalable system treats

water from various sources, including city water, recycled treated

water, and deep well water.

Introducing

Fluidyne International's patented integrated solution for continuous

water filtration and disinfection, preventing scale formation,

inhibiting bacteria, corrosion, and biofilm growth while conserving

water and reducing power consumption. This scalable system treats

water from various sources, including city water, recycled treated

water, and deep well water.

Industrial and commercial facilities utilize cooling tower systems to absorb warmth. Cool water circulates through higher temperature areas, and the heated water is distributed into the ambient air, releasing excess heat and recycling the cool water into the cooling loop. Recycled water entrains dust, dirt, and debris from the surrounding environment. Microorganisms like bacteria and algae thrive in warm, moist environments, contributing to biological growth and fouling. Contaminants such as minerals, pipe-scale, rust/corrosion by-products, and organic compounds reduce flow efficiency, cause corrosion, and damage system piping and components.

The Fluidyne International system optimizes the entire approach to cooling tower water treatment in a single turnkey package:

-

An optimized filtration system minimizes installation footprint and reduces cleanable and disposable filter media.

-

Significantly reduces or eliminates the need for biocides and hazardous disinfectant chemicals such as chlorine and bromine, reducing costs, storage needs, and exposure risks.

-

Replaces complex chemical treatment systems, minimizing maintenance and fugitive emissions.

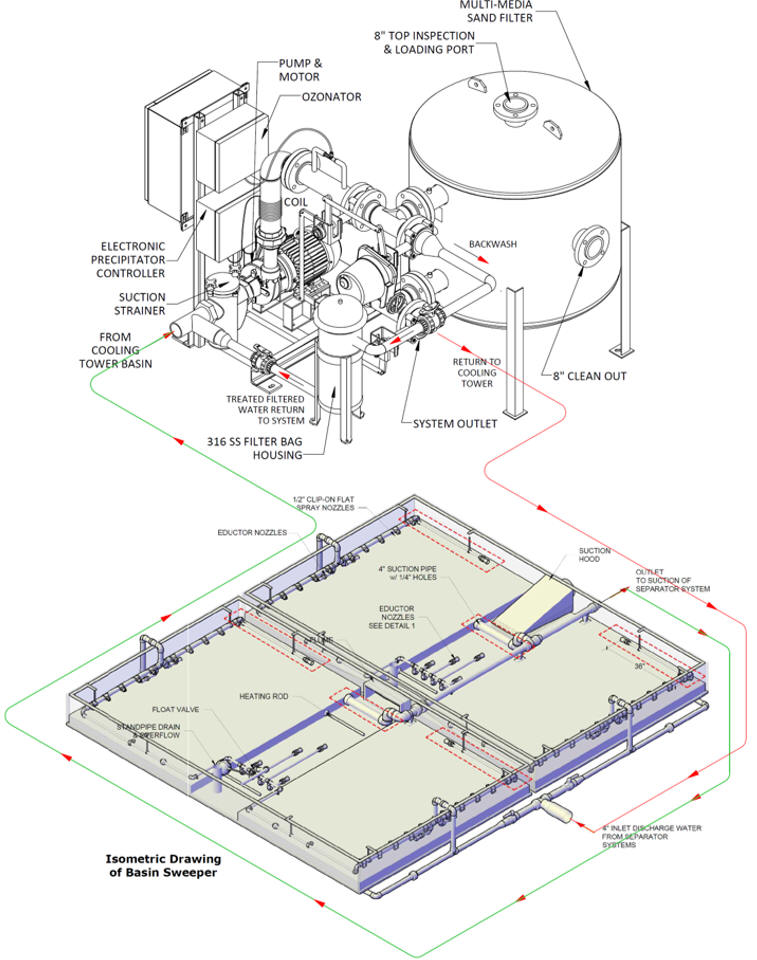

System Components and Functionalities:

-

Water Basin: Receives water from a source via an inlet.

-

Side-Stream Treatment System: Features multiple filtration and/or disinfection mechanisms.

-

Feed Conduit: Transfers water from the water basin to the side-stream treatment device.

-

Return Conduit: Sends a portion of treated water back to the water basin.

Features and Mechanisms:

-

Rotating Nozzles and Eductor Nozzles: Enhance water movement in the water basin.

-

Electronic Descaler and Frequency Resonator: Treat water in or adjacent to the water basin.

-

Sintered Screen: A screen within the water basin for filtration, composed of frame, water tubes, and nozzles.

Side-stream Water Treatment

Options:

-

Centrifugal Separator: Separates particles as fine as 10 microns without physical screens or media, making it maintenance-free.

-

Copper and Silver Ion Injection: Denatures bacteria and breaks down biofilm.

-

Multi Media Filtration System: Contains sand, zeolite, activated carbon, pebble lime stones, UV light, and ionizer.

-

UV Light Dispersion: Destroys microorganisms' DNA with short-wavelength UV light.

-

Ozonator: Generates ozone to oxidize impurities and act as a disinfectant.

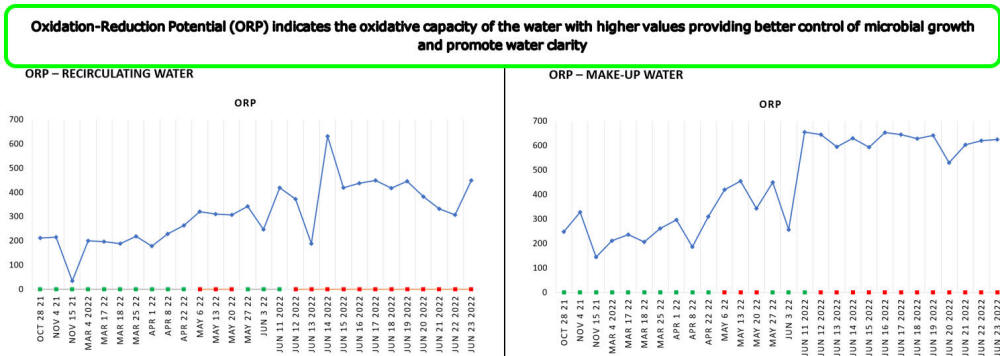

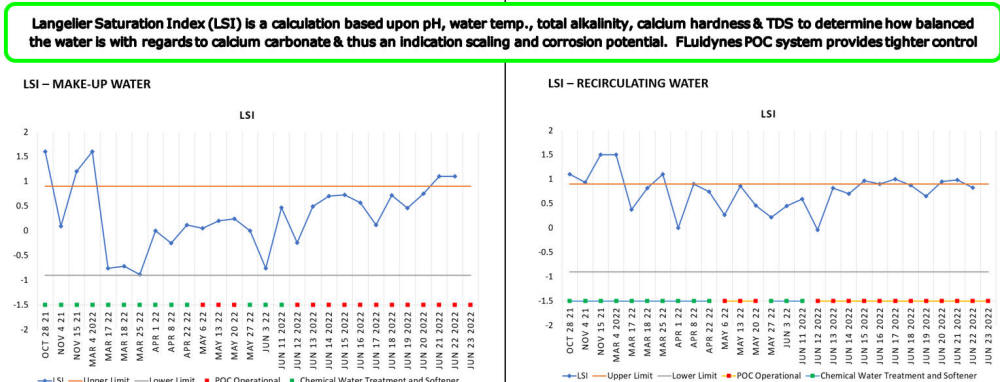

Water Quality Monitoring: Utilizes Langelier Saturation and Ryznar Stability Indexes (LSI & RSI) to assess the corrosivity or scale-forming tendencies of water based on pH, temperature, TDS, hardness, conductivity, and Oxidation-Reduction Potential (ORP).

Cost Savings: Recent case study for a 1500-ton cooling tower system:

-

25% reduction in make-up water, saving 3,000,000 gallons and $10,000/year.

-

50% reduction in bleed water sent to the sewer, saving 2,000,000 gallons and $10,000/year.

-

Estimated $40,000/year saved for sewer diversion.

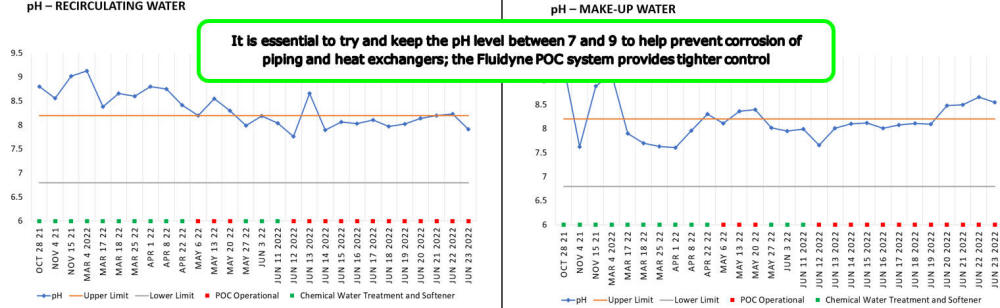

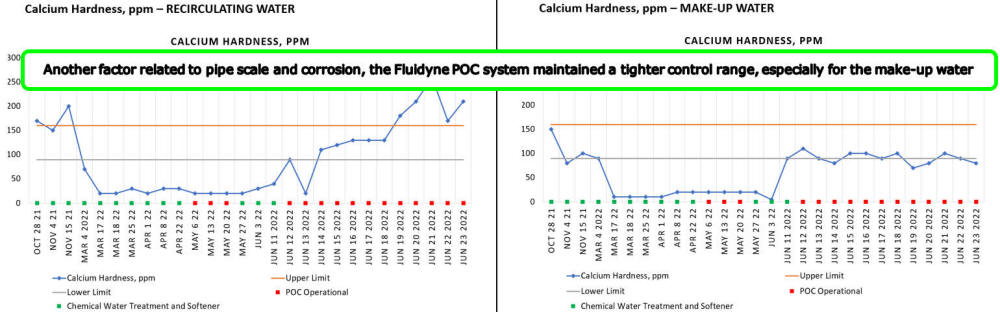

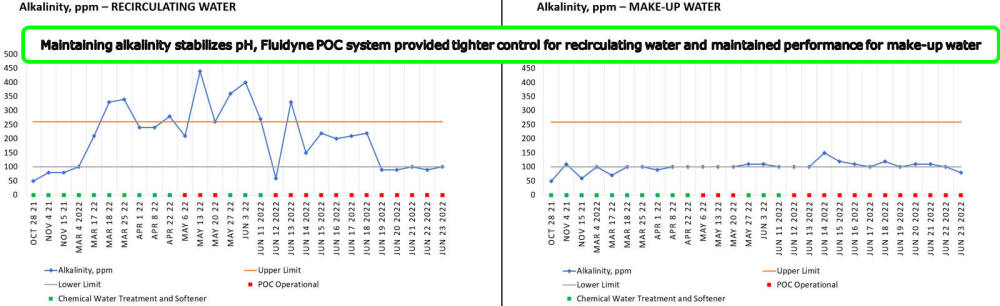

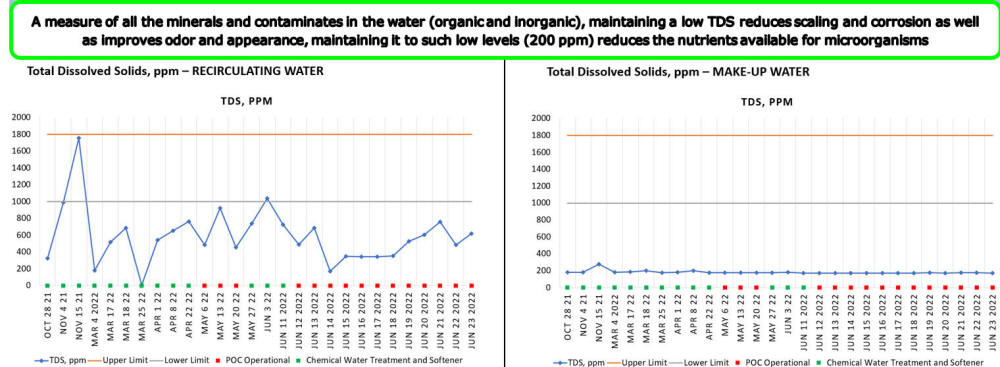

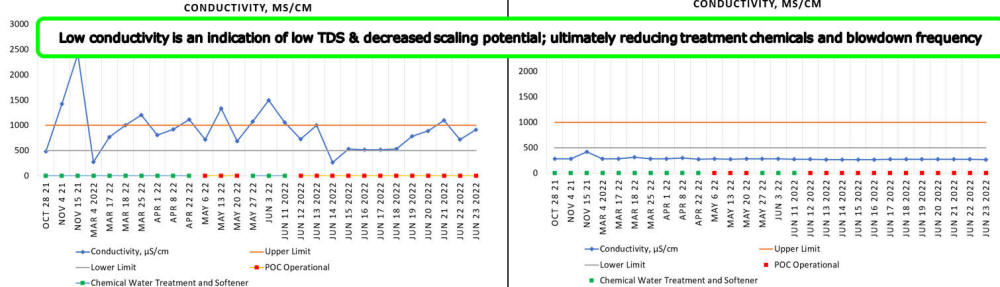

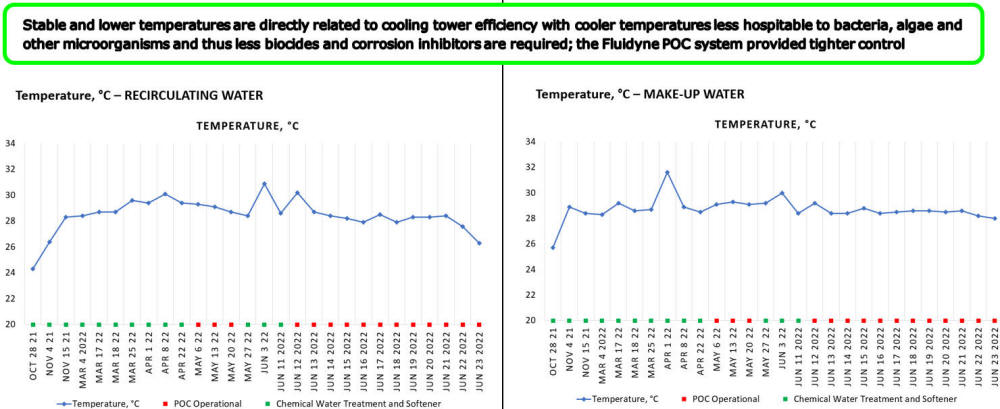

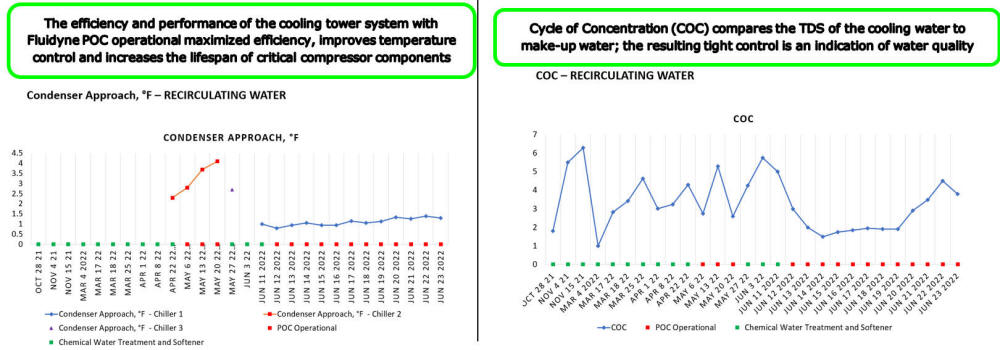

Chemical vs. Fluidyne Intl. Non-Chemical Approach to Water Treatment Results

Following are several charts to provide an illustrative comparison of a customers existing system to a proof of concept (POC) Fluidyne International non-chemical water treatment system. The green ticked dates represent the customer operating their existing system and the red ticked dates represent operation using the POC system. Spoiler alert - in every case the POC performance was an improvement to the customers conventional chemical based water treatment system.

Water Quality Analysis: Summary of water quality improvements with the Fluidyne International system:

-

Tighter pH control.

-

Improved hardness and alkalinity control.

-

Consistent TDS and conductivity.

-

Reduced temperature variability.

-

Significant improvements in ORP and LSI.

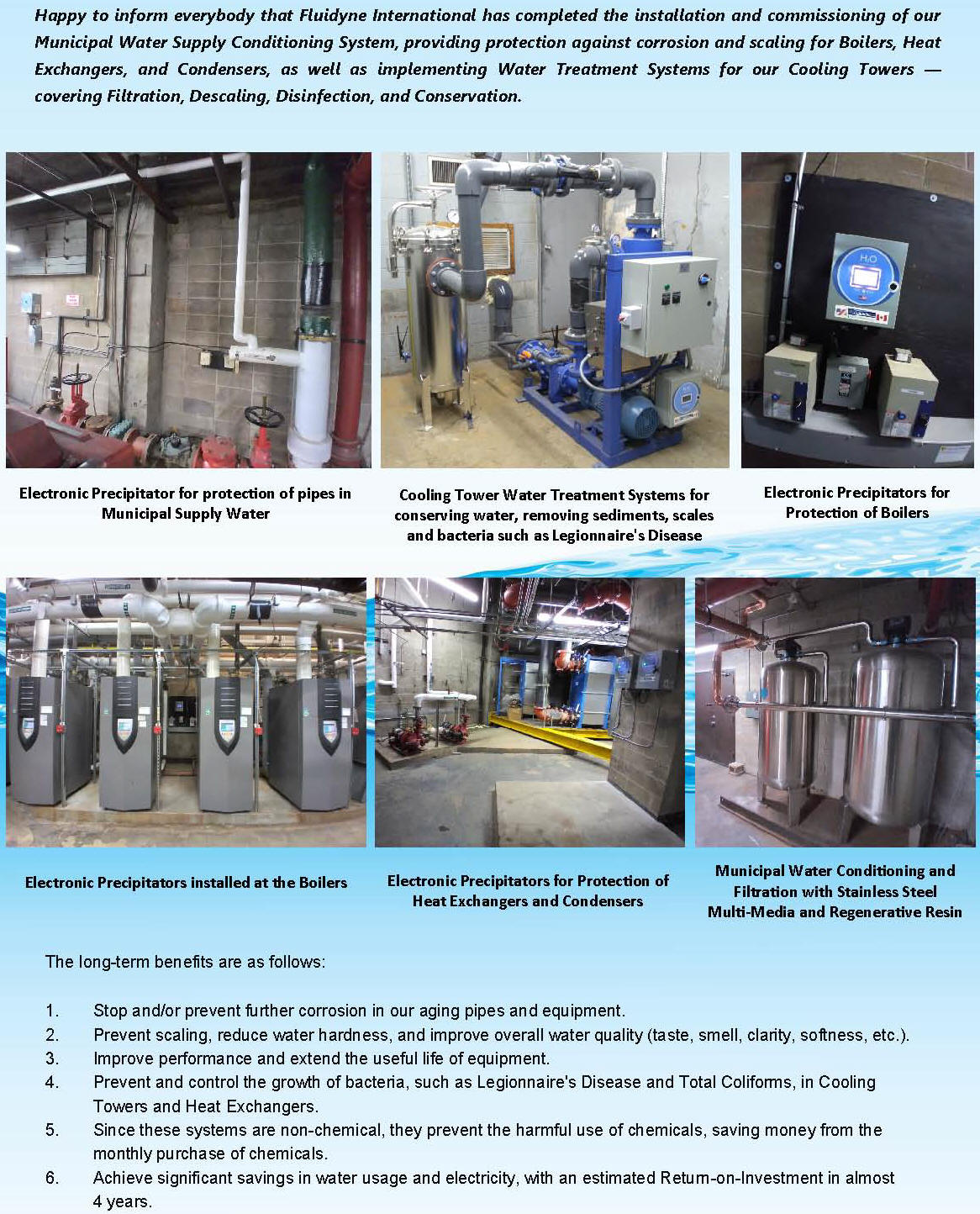

Fluidyne International announced the successful commissioning of their most recent system in January 2024:

Fluidyne International's patented system, operational in two New Jersey condominium complexes, offers significant cost savings and reduced chemical use. Do you have a chemical based water treatment system that might benefit from our non-chemical approach? Perhaps you are engaged in the sales and service of industrial filtration equipment, HVAC or cooling tower maintenance? We are forming a network of trained sales partners to provide this turnkey water treatment system throughout North America. Contact us to learn how we can put our system to work for you or to inquire about our limited sales distribution network and how you can differentiate yourself from the competition with this unique system approach to non-chemical water treatment.