Temporary Strainers for Pipeline Commissioning

Temporary strainers are designed for temporary installation during commissioning of new pipelines and flushing pipelines after modifications and typically removed once the system has been "flushed clean". They are installed upstream of pumps and other equipment to protect them from particles that would damage them.

There are three versions of temporary strainers:

-

Temporary cone strainers (nicknamed witch hat strainer)

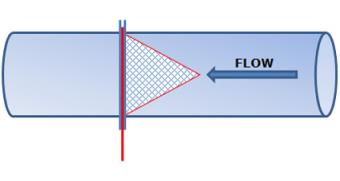

Cone style temporary strainers can be

installed with the pointy end either facing down stream (with the flow)

or upstream (against the flow). They are typically pointed upstream with

particles tending to collect from the outer sections of the pipe inward;

this

orientation is better for higher velocity flow rates. If facing

downstream, particles begin to collect in the center section because the

velocity is typically higher in the center portion of the pipeline.

Since this is the same direction a basket style would be oriented, a cone

strainer might be used to maximize the open area ratio.

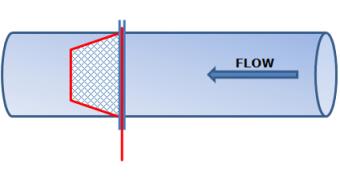

Basket style temporary strainers are oriented facing

down stream (with the flow) and the particles begin to collect in the flat

section. Basket style strainers have less volume and surface area than

the cone style temporary strainer and therefore a slightly higher pressure

drop; their open area ratio is typically 100-150%.

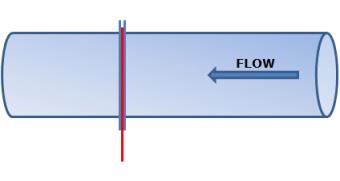

Plate style temporary strainers are essentially a

perforated plate sandwiched between two pipelines; this configuration

provides the least amount of surface area (open area ratio <100%, so a

higher differential pressure than a cone or basket style which has more

surface area), however it is also the easiest to

install and remove from pipelines because they do not need to be spread

apart very far. All temporary strainers can be mesh lined, the mesh

is always on the upstream side, meaning the force of the flow is pushing it

against the underlying support perforation, so when ordering a mesh lined

cone strainer you need to advise the intended orientation.

Temporary

strainers are manufactured in carbon steel, 304SS, 316SS and Monel

materials.