Eaton Model 50 Duplex Strainers

The Eaton model 50 style duplex strainers are used for 5", 6" and 8" pipelines and are a very compact, easy to operate style. These are cast products available in cast iron, steel, 316SS and bronze. We wrote an article answering the question What are the differences between simplex and suplex strainers? which helps you decide if a duplex strainer is the best style for your application.

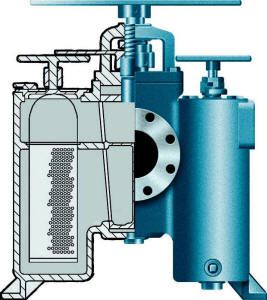

There is a lifting jack built into the strainer body for lifting the diverter plug off of the valve seat. After diverting the flow, the lifting jack is used to reseat the plug. The lifting jack is specially designed to lift and seat the plug easily, even under high pressures. A built in stop limits the distance the diverter plug can be raised. This minimizes the possibility of material bypassing the plug while it is rotated. It also reduces debris from building up under the plug and making it difficult to reseat.

The seal between the plug valve and seat is a metal-to-metal seal, hence the necessity of first lifting the plug prior to diverting flow and then reseating the plug on the seat. The standard diverter plug is made of cast bronze, as it is softer than cast iron, steel and 316SS steel, so if there is wear, its' the replaceable plug valve that wears and not the strainer body which serves as the valve seat. We do offer 316SS diverter plugs for applications that require it and as long as the lifting jack is used, the wear is minimal.

Other important features of Eaton model 50 duplex strainers include quick opening, swing away yoke design covers. No tools are required to remove the covers for quick and easy access to the strainer baskets and they are reattached just as quick as they removed.

Draining of the basket chambers is simplified with the standard NPT drain taps – and all sizes are provided with mounting legs for bolting the strainer to the floor for a solid installation.

Eaton model 50 duplex strainer specifications and drawings