Maximizing Filtration Efficiency: Unveiling the Secrets of Strainer Baskets

At

the very heart of all industrial simplex and duplex pipeline

strainers is the internal element often referred to as a "strainer

basket." This article will describe how most strainer baskets and

elements are designed, highlighting little known modifications which

can significantly improve performance of your filtration system.

At

the very heart of all industrial simplex and duplex pipeline

strainers is the internal element often referred to as a "strainer

basket." This article will describe how most strainer baskets and

elements are designed, highlighting little known modifications which

can significantly improve performance of your filtration system.

In its simplest form, a strainer basket is a basket shaped object with a handle designed to collect particles entrained within a liquid.

The foremost important aspect of a strainer basket is its overall size, more specifically, its total surface area. Strainer baskets are often not interchangeable between brands; an Eaton strainer basket will not fit into a Titan strainer and vice-versa, even when the strainer bodies have the same "connection size." This is because "strainer size" is a reference to the inlet and outlet nozzle internal diameter and not correlated to the strainers differential pressure for a given flow rate.

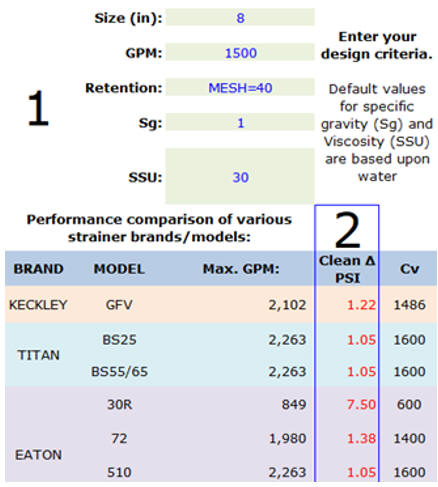

This is why we focus on the open area ratio (OAR), flow coefficient (Cv) and differential pressure values for a specific size pipeline strainer and not just the strainer "connection size" when comparing different models and brands. The Cv value reflects the resistance to flow for a particular strainer design whereas the differential pressure calculation reflects the combination of the strainer housing and strainer basket designs. Comparing the OAR of different models and brands of pipeline strainers which have the same connection size enables you to determine which design is most cost effective for your specific application. Lower cost is almost certainly due to a smaller size housing and strainer basket, thus increasing the differential pressure, liquid velocity, and frequency of basket cleaning. Refer to our articles "When should you clean your strainer basket" and "How to select a pipeline strainer" for additional information.

Open Area Ratio

The proper way to

compare the performance of simplex and duplex strainers is to compare their OAR, which is

the comparison of the open area of the inlet nozzle to the open area of the

strainer basket. Larger ratios equate to a lower pressure drop across the

strainer body and reduced frequency of basket cleaning because their surface

area and volume are larger. Some strainer manufacturers publish the surface

areas of their strainer baskets and others do not but they will provide that

information if you request it. "Open Area" (OA) is the area of the openings

within the strainer basket, and it is expressed as a percentage of the total

surface area. Each perforation size has a different OA value. When the

desired retention is finer than the finest perforation available, a separate

layer of wire mesh is attached to the perforated substrate. The mesh also

has a certain percentage of OA, thus when combined with the perforated

substrate the total OA is reduced. You can calculate the surface area of a

strainer basket and use the manufacturers OA figures for perforations and

mesh to determine the overall OA of the strainer basket.

We automate the strainer comparison process to compare several brands and models simultaneously with a web-based calculator. Input the strainer size, flow rate, basket retention, specific gravity and viscosity and you can see which strainers have the lowest differential pressure. For additional information review our article "How to compare and select cast simplex strainers".

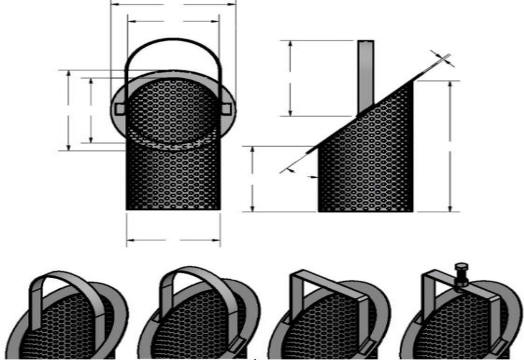

The body of most strainer baskets consists of a cylinder having one open end; the top end is open, and the bottom end is solid. The flow path for this style of strainer basket is "over the top." There is a sealing ring slightly larger in diameter then the body to support the basket within the housing and to provide a bypass free seal between the strainer body and basket. Material accumulates against the interior circumference area of the basket and falls to the bottom depending upon the liquid characteristics, including flow velocity and nature of the particles.

The body

of the strainer basket is made from perforated stainless steel although can

be made from other alloys if needed. When fine retention is required, a wire

mesh is welded to the interior of the strainer basket. The perforated

substrate supports the fine mesh material to withstand higher differential

pressures. Some manufacturers sandwich fine mesh between layers of

perforated material for added strength.

The body

of the strainer basket is made from perforated stainless steel although can

be made from other alloys if needed. When fine retention is required, a wire

mesh is welded to the interior of the strainer basket. The perforated

substrate supports the fine mesh material to withstand higher differential

pressures. Some manufacturers sandwich fine mesh between layers of

perforated material for added strength.

Strainer baskets are designed to withstand non-shock differential pressures up to 20 or 30 PSI; higher pressure systems or when there is increased potential for higher differential pressures require using thicker materials and supports which may reduce the overall OAR. Strainers should be selected such that the clean basket differential pressure is <=2 PSI and cleaned once the differential pressure reaches 8 PSI. Differential pressure increases exponentially when subjected to a continuous particle load due to the systematic reduction of OA available. If you set your basket cleaning differential pressure too high, you may not have enough time before the differential pressure exceeds the baskets design. "Water hammer" is another aspect to consider when establishing the initial and cleaning differential pressure thresholds.

Basket handles serve two other functions in addition to lifting it from the strainer body without contacting the process liquid. #1: The handle is designed to be compressed between the strainer housing cover and the interior strainer basket support ring. The pressure exerted forms a tight seal to prevent liquid from bypassing the strainer basket. Some designs rely on precision mating surfaces for a metal-to-metal seal and others incorporate an o-ring under the strainer basket sealing ring to form a bypass-free seal with the strainer body. #2: The forced tension of the strainer basket against its seat also helps prevent the basket from wear due to spinning; this is something that can happen when the handle is damaged, or the liquid velocity is too high. The mechanical rubbing between the strainer basket and strainer body will damage the surfaces of both components.

Alternate Designs

Some manufacturers offer unique strainer body and basket designs for specific types of applications.

An example are strainer baskets having a side entry flow path. This design reduces turbulence and differential pressure; it is preferred for large capacity suction strainers where it is desirable to maximize the NPSHa at the pump inlet.

Other designs have a slanted basket ring; the loss of

surface area due to cylindrical length can be offset by increasing its

diameter. An advantage of the slanted basket design is lower differential

pressure and zero chance of spinning within the strainer housing under high

velocity flow conditions.

Other designs have a slanted basket ring; the loss of

surface area due to cylindrical length can be offset by increasing its

diameter. An advantage of the slanted basket design is lower differential

pressure and zero chance of spinning within the strainer housing under high

velocity flow conditions.

Let us put our extensive experience and knowledge to work for you! Explore our website for many articles like this to better understand your industrial filtration options, which includes performance comparison between different brands and models of simplex and duplex strainers. Our awareness of the many strainer variations available will help ensure you purchase the best pipeline strainer design for your specific application. Call, email, or live chat online today!