Keckley Model DPX Duplex Strainers

threaded and flanged duplex strainers

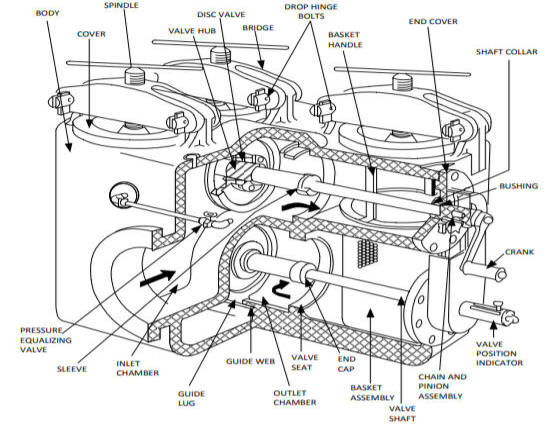

The Keckley DPX style cast duplex strainers are designed for continuous duty applications where it is not desirable to shut the process flow off for cleaning the strainer basket. Diversion of flow from the basket chamber in use (the chamber under the handle) for the 3/4" through 8" sizes is accomplished easily by simply rotating the handle 180º. The 10" through 20" sizes are crank operated to move the respective valves to opposite seats as pictured below. The seal between the valves and strainer body are metal-to-metal for both designs and thus slight leakage into the isolated strainer basket chamber can be expected, especially after some wear.

Keckley's duplex strainer baskets are easily accessed without tools due to the knob style or yoke-style closure design. The strainer baskets have an o-ring seal to maximize efficiency, ensuring minimal particle bypass.

Differential pressure taps are provided for use with Keckley's basket clogging indicator or your own differential pressure gauge. We can supply Keckley duplex strainers with clogging indicators, a pair of standard pressure gauges or differential pressure gauges as desired.

Navigate to the desired material of construction to use our online differential pressure calculators. This is the link to Keckley duplex strainer catalog page and drawings.