PTFE, PVDF, and PPL Baffle Strainers: Efficient Filtration Solutions

Understanding the Difference: Baffle vs. Start-Up Strainers

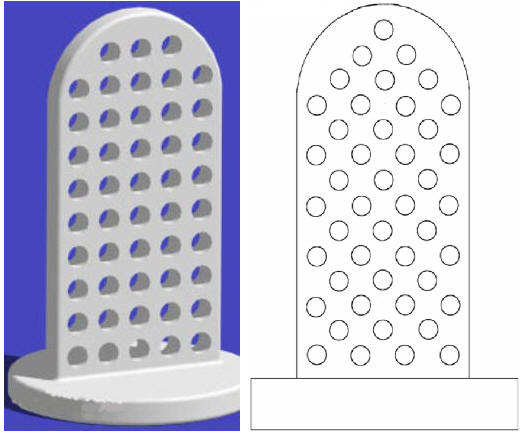

Our comprehensive range of baffle strainers are designed to provide efficient and reliable filtration solutions for various applications. These strainers, available in PTFE, PVDF, and PPL materials, offer enhanced particle removal and improved flow characteristics compared to standard start-up strainers. You can essentially use an exiting tee fitting to create a tee strainer with this baffle or we can provide the entire tee strainer assembly. Our non-alloy tee strainers are designed for liquids which are aggressive to most alloys and for use in PTFE, PVDF and PPL piping systems.

Baffle Strainers: Baffle strainers are designed for continuous filtration in demanding industrial processes. Unlike start-up strainers that are used temporarily during pipeline start-ups, baffle strainers remain in place to provide ongoing protection against contaminants. They feature a unique design that directs the flow of fluid through baffles or vanes, enhancing filtration efficiency.

Start-Up Strainers: Start-up strainers, as the name suggests, are used specifically during the initial phases of a pipeline's operation. They are temporary solutions intended to capture debris, rust, and particles that may be present during start-up. Start-up strainers are removed once the system is operational and stable.

Application Example and Benefits

Baffle strainers excel in applications where a high volume of fluid needs continuous filtration. Industries such as petrochemicals, refining, and wastewater treatment benefit from the enhanced particle retention and improved flow characteristics provided by baffle strainers. The baffles within the strainer also help reduce turbulence and pressure drops.

Start-up strainers are indispensable during pipeline commissioning to prevent damage to equipment and downstream processes. They find use in industries like construction, pharmaceuticals, and food processing. Start-up strainers are quick to install and remove, making them ideal for temporary filtration needs.

Choose the Right Solution

Selecting between baffle and start-up strainers depends on your application's requirements. For continuous filtration needs, baffle strainers offer long-term protection, while start-up strainers provide essential temporary filtration during initial pipeline operations. Reach out to us to explore our range of PTFE, PVDF, and PPL baffle strainers and determine the optimal solution for your filtration needs.