Y Strainer vs. Basket Strainer Design

Differences between Y and Basket Style Strainers

Both Y and basket style strainers require isolating the strainers inlet and outlet to physically clean the straining element (thus interrupting the process flow), however there are significant functional differences that, depending upon specific application characteristics, will determine whether a Y or basket style strainer is best style for your application.

Y Strainers

Y Strainers

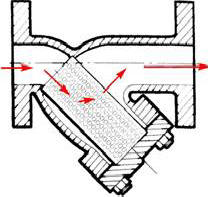

Although Y strainers are applied to liquid applications regularly, they were

initially designed for steam, air and other inert gases to protect downstream

equipment from a “particulate upset condition”; what we mean by that phrase is

that normally particles are not expected, however as piping systems age bits of

pipe scale, gaskets and other materials can become entrained in the process

flow. Y strainers have a “blow down” port for this reason, bits of pipe

scale can be “flushed” from the screen chamber by attaching a valve to this port

and when opened to atmospheric pressure the material within the screen chamber

is “flushed” through the valve.

The key takeaway about the design of a Y strainer is that it is designed to

protect downstream equipment from material that isn’t continuously present in

the process flow. Another way to describe this is that the percentage of

particles to be removed from the process fluid should be relatively low if you

are going to use a Y strainer.

There isn’t anything “wrong” about using a Y strainer for liquid applications;

in-fact Y strainers have some advantages:

•

•

Perhaps the most significant downside of a Y strainer when compared to a basket

strainer is the “open area ratio”. The open area ratio (OAR) is the ratio

of the cross-sectional area of the inlet/outlet port compared to the open area

of the element.

A straining element is either perforated or having a perforated substrate with a

mesh lining for finer retention. Generally speaking, the finer the

retention, the less open area the straining element has; why is this important?

The percentage of open area combined with the flow coefficient (CV)

of the strainer itself (design dependent) will determine the pressure drop

across the strainer for a given flow rate. Generally speaking the higher

the CV, the less of a pressure drop there will be across the strainer

body; the open area of the straining element will determine how much more the

initial differential pressure will increase.

Since Y strainers were not designed to continuously remove particulate, their

design (strainer element chamber and element dimensions) are only designed to

provide straining ratios of 1:1, 2:1 and perhaps in some cases 3:1, meaning at

best the element has 3 times open area compared to the diameter of the

inlet/outlet connection.

Basket Style Strainers

Basket Style Strainers

The phrase “Simplex Strainer” has become ubiquitous for basket strainers even

though Y, Tee and other variations are also “simplex” in nature, so for clarity

we’ll refer to them as basket strainers.

Getting back to the OAR aspect, the real differentiator, basket strainers

typically have an OAR of 6:1 and sometimes as high as 8:1; significantly more

than a Y strainer. This is why basket strainers are used for applications

that have a continuous particle load. Thus an application such as

reclaimed cooling tower water, where there’s an expectation of particulates that

need to be removed all the time, is a better fit for a basket strainer than a Y

strainer.

The difference in straining ratios is approximately the difference in frequency

that the straining element will need to be cleaned, thus you would expect to

clean a Y strainer screen that has a 2:1 OAR about 3 times as often as you would

clean a basket strainer having a 6:1 OAR.

In summary, most liquid filtration applications that are either batch processes

or where it’s acceptable to interrupt the flow to clean the straining element

will be best suited for basket strainers due to their higher OAR and physically

larger holding capacity. Y strainer applications are typically for inert

gasses and for liquid applications where the particle loading is very low or

only expected during an upset condition.