How to Choose Between a Simplex Strainer vs Y Strainer

Comparison of basket and Y strainers

Wye ('Y') strainers and Pot (aka. Tee or 'T') strainers have many similarities, so how does one decide which style is the best fit for an application?

Similarities

Y and T strainers are both simplex style pipeline strainers designed for batch applications with a light particle load; to clean the internal screen requires interrupting the process flow.

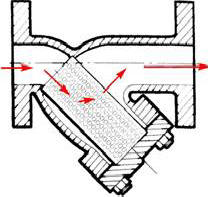

Y Strainers

Y Strainers

Although commonly used for

liquid applications, the use of Y type strainers were initially for steam, air

and other inert gases to protect downstream equipment from a

"particulate upset condition" such as protecting steam condensers from

rogue pipe scale. Y strainers have a blow-down port for steam

applications and this flushing capability is a characteristic that T

strainers do not have. While blow-down may work for aqueous

applications, the efficiency of flushing depends upon the particles

retained not becoming embedded within the element.

Although it is

possible to fabricate Y strainers to satisfy specific applications, the

majority of Y strainers are cast items, thus non-customizable.

It is common for Y strainers to be available in 1/4" through 10" sizes

and because they are a cast item manufactured in foundry-pour based

quantities, shipment is often made within just a day or two after

receipt of an order. The available pressure class ranges and breadth of

materials of construction (iron, steel, bronze, and 316SS) are also

advantages of Y strainers.

The open area ratio (OAR) for Y

strainers is typically a little better than T strainers; most of our Y

strainers have a 3:1 OAR wheras the larger size T strainers have an OAR

of <= 2.

Y strainers have a screwed or bolted chamber cover for

screen access and are installed such that when opened the process fluid

will fall/drain out.

T strainers

T strainers

T strainers usually begin at

larger sizes (2") and can be fabricated for 24" or larger pipelines. As

a fabricated product, the lead times range from 8-12+ weeks (inclusive

of generating approval drawings and manufacturing).

While the OAR for a T strainer is typically less than a

comparable size Y strainer, its' flow capacity is higher.

This is attributable to the flow path within a T strainer having a

"straight-through" design as well as the convoluted element shape.

When installed horizontally, the chamber cover of a T strainer

can be opened without the process fluid draining from the chamber; this

might be a desirable feature with valuable or hazardous process fluids.

Summary

Y strainers typically offer the best

value in terms of initial cost, lead time and overall flexibility which

include materials of construction, pressure class, and inherent built-in

blow-down port/drain.

T strainers are used when transferring

fluids at higher velocities (equates to higher flow rates), for larger

pipelines, applications that require special features and for quicker

access to the straining element.