Differences between Simplex and Duplex Strainers

Comparison of simplex and duplex basket strainers

Basket strainers are important pieces of equipment used in a wide array of filter applications. It is a closed pressure vessel with a cleanable screen element that filters particulate out of the process liquid to protect valves, pumps, and machines downstream. These strainers are designed to be installed horizontally and to provide quick access to the strainer basket for cleaning. The two most common styles of basket strainers are simplex (single basket) and duplex (dual basket).

Simplex

Simplex Strainer

Simplex Strainers

With the simplex design, baskets can be removed for cleaning only when the process is shut down and thus are used for "batch" applications or processes which can be interrupted for basket cleaning. Usually, shut-down time is minimal due to the quick-opening basket chamber cover closures.

Once the flow has stopped and the strainer

chamber isolated, a vent valve is used to relieve the chamber pressure

and to facilitate quicker draining with the drain valve or plug at the

chamber bottom.

Once the basket has been cleaned of particulate, it is placed

back in the strainer and the application process may continue. Its

common practice to use a spare basket to quickly replace the dirty

basket and then the dirty basket can be cleaned and set aside for the

next cleaning cycle.

Simplex strainers are available

in both cast and custom fabricated designs to match the pipeline

pressure class and material.

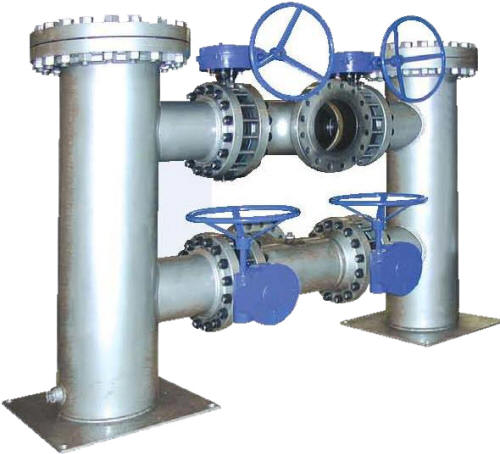

Cast Duplex

Strainer

Custom Fabricated Duplex Strainer

Duplex Style Strainers

The duplex

strainer design is for continuous duty applications which cannot

tolerate an interruption in flow for basket cleaning; i.e. the system

flow cannot be interrupted.

A duplex strainer is essentially two simplex

strainers connected with a three-way valve used to divert flow from the

dirty basket chamber to the clean basket chamber.

The style of valve used to divert the flow

differs with cast and custom fabricated designs. Cast designs

require only a lever to divert the flow because there's one three-way

valve being operated. The flow remains continuous because as one

side of the valve closes, the other side opens.

The custom fabricated designs often use four

butterfly valves; sometimes they can be linked to a single operator, however more often they need to be individually opened and

closed, thus the order they are manipulated becomes important. You

begin by opening the inlet valve to the clean chamber, followed by

opening the outlet valve for the clean chamber, then closing the outlet

valve for the dirty chamber and finally closing off the inlet valve to

the dirty chamber.

Once the dirty chamber is isolated, the

access and change-out procedure is the same as it is for a simplex

strainer.

The choice of a cast or custom fabricated design is typically dictated by the design criteria for the application; castings are suggested wherever applicable to reduce cost and lead time.

Sizing Guidelines

There are four general steps to take when

sizing for a strainer:

1) Ensure that the pipeline flow velocity and

clean differential pressure falls within the standard design range of

the strainer.

2) The strainer should be compatible with the

process fluid and satisfy both design pressure and temperature

requirements.

3) Consider the quantity, type, and nature of

debris to be removed.

4) Choose the proper screen perforation/mesh

for your application, if you choose something unnecessarily restrictive

it will increase the clean differential pressure and thus require more

frequent cleaning.

Cv Value

Basket strainers typically have an open area

ratio (OAR) of 6:1 and sometimes as high as 8:1. This is the ratio of

net free area of the screen to pipe area. The area is calculated with a

clean basket and as the basket begins to clog, the ratio will drop. As

material collects on the basket surface, the available amount of open

area is reduced thereby resulting in reduced flow through the strainer

and/or exhibiting a higher differential pressure.

Most strainer elements are perforated and for

finer retentions a second layer of wire mesh cloth is welded to the

basket interior.

The finer the retention, the less open area

the straining element has because there is a certain amount of

structural material required for a sturdy strainer basket design.

Strainer baskets are generally designed to withstand up to 20 PSI

differential pressure, however a properly sized strainer will begin with

<=2 PSI differential pressure and be cleaned once the differential

pressure increases by 5 PSI because at this point nearly all the basket

surface area is covered and the differential pressure will begin to

increase exponentially. The "trick" is to allow sufficient time to

divert flow before the differential pressure increases sufficiently to

damage the strainer basket.

In summary, it is important to know if an

application is batch or continuous before deciding between a simplex and

duplex strainer design.