Filtration Options for Gelatinous Particle Retention

Efficient filtration of deformable particles

requires special consideration of differential pressure and the medium used

for retention. This article describes the critical design criteria for

proper vessel sizing and the specialized filter elements and filter bags

designed specifically for filtration of gelatinous particles.

Examples of Gelatinous Particles

Solid-like particles

consisting of interconnected microscopic structures which are easily

deformable are generally referred to as gelatinous. Polymers, grease,

organic material, ink and paint are examples of gel-like particles which are

difficult to retain with ordinary filter mesh because the particle is easily

deformed and extruded through mesh-like structures.

Role of

Differential Pressure

Role of

Differential Pressure

A starting differential pressure across a

clean filter element of 2 to 3 PSI is acceptable for most filtration

applications because when the element is about 75% clogged the differential

pressure will have increased to about 8-12 PSI which is when it should be

cleaned or replaced. Assuming a consistent particle load, the differential

pressure increases exponentially as the free area of the element is reduced

from particles entrained within the filter media.

Monitoring your

differential pressure is especially important for retention of gel-like

particles as they are more likely to deform and pass through your filter

media at higher differential pressures. Thus, a consequence of gelatinous

particle filtration is increased frequency of element cleaning or

replacement.

Increasing the size of the filter element will both

reduce the initial clean differential pressure across the element and

provide extra retention area to reduce the frequency of maintenance

required. The trade-off is an initially more expensive (larger) filter than

the flowrate alone necessitates for the benefit of less down time, personnel

exposure to the fluid and reduced media replacement during the years that

follow.

Types of Filters for Gelatinous Particle Filtration

-

Filter Cartridges

-

Filter Bags

-

Automatic strainers with permanent SS elements

Filter Cartridges

Filter Cartridges

The

LOFPLEAT GG is a pleated filter cartridge made from borosilicate micro

fiberglass, a firm substrate forming a torturous path providing both depth

and surface filtration. These cartridges are about 90% efficient for

retention of particles as fine as 1 micron and support a flow rate of

approximately 1 GPM per inch length of the cartridge, which can be up to 40

inches long. High flow rate applications require a cartridge filter housing

designed to hold multiple filter cartridges.

The

LOFPLEAT HF-G is a

higher efficiency version in support of higher flow rates; approximately 8

GPM per inch length of filter cartridge with cartridge lengths up to 60” in

length.

LOFMET porous alloy filter cartridges are another example of

a rigid torturous path substrate filter cartridge suitable for deformable,

gel-like solids retention.

Filter Bags

As

compared to filter cartridges, filter bags generally have a larger surface

area and the housing design significantly reduces the chance of particle

bypass during filter media changes. While it might be possible to re-use

rigid design filter cartridges if they can be chemically cleaned, filter

bags are designed to be disposed after use due to the intricate microfiber

design which makes cleaning them almost impossible without reducing their

efficiency.

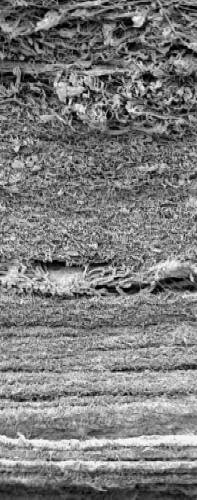

Filter bags designed to retain gelatinous particles are

made from multiple layers of meltblown polypropylene fibers to form

increasingly complex pathways through the media, thus provide very efficient

depth filtration.

The

LOFCLEAR 500 filter bags have a pleated outer

layer to pre-filter larger particles and when the differential pressure is

low, gelatinous particles will be retained on this outer layer also. The

pleated design of the pre-filter layer equates to 32 ft2 of surface area,

about 6 times the 5.2 ft2 of surface area of the underlying #2 sized filter

bag.

The

LOFCLEAR 500 filter bags have a pleated outer

layer to pre-filter larger particles and when the differential pressure is

low, gelatinous particles will be retained on this outer layer also. The

pleated design of the pre-filter layer equates to 32 ft2 of surface area,

about 6 times the 5.2 ft2 of surface area of the underlying #2 sized filter

bag.

To increase the particle retention capacity and retain

gelatinous/deformable solids the LOFCLEAR 500 has multiple layers, each

increasingly complex to retain finer and finer particles. This torturous

pathway also entraps deformable particles as the differential pressure would

need to be quite high to extrude such particles through multiple layers of

melt-blown polypropylene fibers that are increasingly dense.

The

LOFCLEAR 500 has a fully welded design to maintain flow path integrity as

well as ensuring the strength of the filter bag to reduce the chance of

rupture as it can hold just over 2 lbs. of particles. The outer layer

consists of a fine mesh to prevent fiber migration of the meltblown fibers

of which the filter bag is constructed. The polypropylene fibers used in the

melt blown process do not contain silicone or other crater-forming

substances and thus LOFCLEAR 500 filter bags are often used for filtration

of automotive coatings and other critical coating processes. A more thorough

description of the melt-blown design with microscopic pictures illustrating

the fiber web is online in our

filter bag materials article.

The

LOFCLEAR 500 has a fully welded design to maintain flow path integrity as

well as ensuring the strength of the filter bag to reduce the chance of

rupture as it can hold just over 2 lbs. of particles. The outer layer

consists of a fine mesh to prevent fiber migration of the meltblown fibers

of which the filter bag is constructed. The polypropylene fibers used in the

melt blown process do not contain silicone or other crater-forming

substances and thus LOFCLEAR 500 filter bags are often used for filtration

of automotive coatings and other critical coating processes. A more thorough

description of the melt-blown design with microscopic pictures illustrating

the fiber web is online in our

filter bag materials article.

Automatic Filters

Most automatic filter designs rely upon the

filtered liquid to backwash the element, which is often problematic for the

kinds of liquids containing deformable solids such as paint, ink and

lubrication fluids because the backwash volume is significant and its also

“product”. Most backwashing automatic filters involve water or other

non-hazardous fluids because sending the backwash to drain isn’t

problematic. The types of elements used in backwashing filters do not employ

a “torturous path”, rather a perforated or wedgewire structure which

deformable particles could extrude through.

DCF style automatic

filters employ a different approach to cleaning the element. Rather than

backwashing the element, a cleaning disc cycles through the element. Often

referred to as a scraping filter, the internal disc consists of 4 spring

loaded sections to evenly distribute force across the element surface and to

account for eventual wear of the non-alloy cleaning disc. The frequency of

the cleaning stroke is user adjustable.

DCF style automatic

filters employ a different approach to cleaning the element. Rather than

backwashing the element, a cleaning disc cycles through the element. Often

referred to as a scraping filter, the internal disc consists of 4 spring

loaded sections to evenly distribute force across the element surface and to

account for eventual wear of the non-alloy cleaning disc. The frequency of

the cleaning stroke is user adjustable.

When sized to have a low

initial differential pressure and high frequency stroke, particles,

including deformable ones, have a short residence time on the surface of the

element before being swept away. The upwards and downwards force of the

cleaning disc does a great job of maintaining the low differential pressure

and the action is not so harsh against the element as to result in extrusion

of deformable particles.

The particles swept from the element reside

within the lower section of the filter body referred to as the “purge

chamber”. The shape of the purge chamber supports easy flow out of the

filter during the purge cycle. The purge cycle frequency is another

user-programmable characteristic which can be fine-tuned as needed.

The systems differential pressure purges the retained concentrated particle

slurry when its drain valve is briefly opened. When the differential

pressure is low, the cycle time or frequency of purging can be extended.

Alternately it is possible to attach a pump to the drain port to vacuum-out

the particle slurry if the differential pressure is not sufficient for

thorough purging.

Cartridge, Bag or Automatic Filter?

If your application is to remove as much gelatinous particles as possible,

filter cartridges and filter bags will work best. When the loading is very

high and its cost prohibitive to use disposable filter media, the DCF style

automatic filter is a good choice as a pre-filter, perhaps with a filter

cartridge or bag filter installed downstream to retain any remaining

particles.