Which Duplex Strainer Design is the "Best"?

Comparing styles of duplex strainers

One of the most common strainers in piping are duplex strainers, used for applications that cannot be interrupted due to strainer

basket clogging. Automatic strainers are another option to consider,

although due to their complexity are typically only feasible for 8” and larger

pipelines.The Duplex Concept

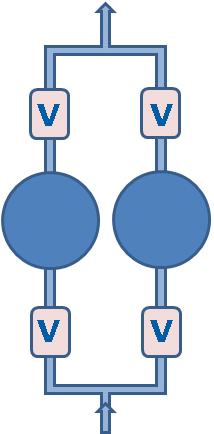

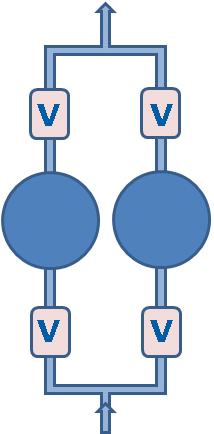

If you are using four valves (one for each strainers’ inlet and outlet), the

operator needs to operate each of the valves in a specific order to ensure

uninterrupted flow.

If you utilize a pair of three-way valves, one on the entrance to the inlet

manifold and the other at the exit of the outlet manifold, the “trick” is to

manipulate each strainer in piping simultaneously. This is where an engineered duplex design

is advantageous, as the strainer bodies and valve actuators are made to simplify

operation.

This style is used by several duplex strainer manufacturers; it is the standard Titan duplex strainer design and Eaton 53BTX duplex strainer design. The Keckley duplex strainer is also similar.

Prior to the valve cartridge style, the plug diverting style represented the

most compact and modern duplex strainer design. This design is used for 6” and

8” size pipelines because most duplex strainers for smaller pipelines are best

served with the valve cartridge style.

The Eaton duplex strainer model 50 is an example of a diverting plug valve style duplex water strainer. This was formerly known as a Hayward duplex strainer model 50, however they sold this product line to Eaton in 2005. If you call or email our office we can cross reference the different part numbers for spares or replacements.

Cast versions using this approach are for pipelines 10”-18” and utilize resilient seated butterfly valves to divert flow from the dirty to clean chamber. A single geared actuator is connected to each of the four valves required for this design. The actuator and associated linkage assures the flow is diverted between the chambers without interrupting flow.

Fabricated versions are used for higher-pressure

applications and when cast iron bodies are not acceptable for 2” to 48”

pipelines. Fabricated versions typically use four gear actuated resilient

seated butterfly valves although it’s possible to use double/triple offset

butterfly valves or ball valves for flow diversion. If there are special

valve requirements, we will typically provide the strainer bodies and flanged

manifolds, letting the customer procure whatever valves they desire.

Fabricated versions are used for higher-pressure

applications and when cast iron bodies are not acceptable for 2” to 48”

pipelines. Fabricated versions typically use four gear actuated resilient

seated butterfly valves although it’s possible to use double/triple offset

butterfly valves or ball valves for flow diversion. If there are special

valve requirements, we will typically provide the strainer bodies and flanged

manifolds, letting the customer procure whatever valves they desire.

This design provides yet another way of simultaneously diverting flow between

strainer basket chambers. An advantage of the sliding valve design is that

the valve is completely out of the flow path.

This design provides yet another way of simultaneously diverting flow between

strainer basket chambers. An advantage of the sliding valve design is that

the valve is completely out of the flow path.

The Duplex Concept

Valve Cartridge Style

This style is used by several duplex strainer manufacturers; it is the standard Titan duplex strainer design and Eaton 53BTX duplex strainer design. The Keckley duplex strainer is also similar.

Plug Diverting Style

The Eaton duplex strainer model 50 is an example of a diverting plug valve style duplex water strainer. This was formerly known as a Hayward duplex strainer model 50, however they sold this product line to Eaton in 2005. If you call or email our office we can cross reference the different part numbers for spares or replacements.

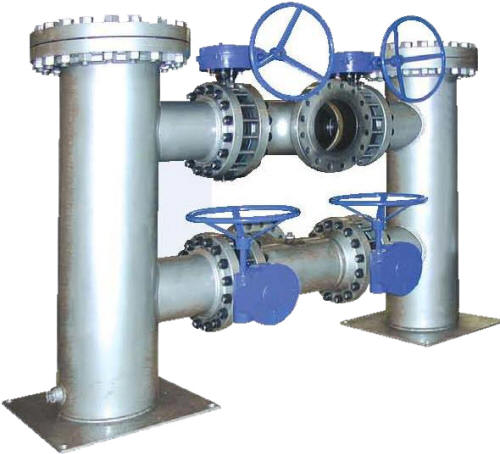

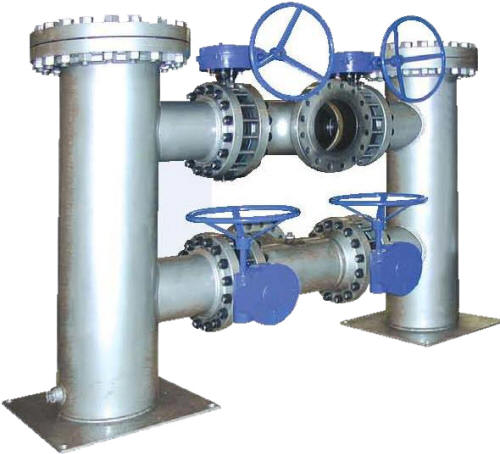

Butterfly or Ball Valve Diverting

Cast versions using this approach are for pipelines 10”-18” and utilize resilient seated butterfly valves to divert flow from the dirty to clean chamber. A single geared actuator is connected to each of the four valves required for this design. The actuator and associated linkage assures the flow is diverted between the chambers without interrupting flow.

Fabricated versions are used for higher-pressure

applications and when cast iron bodies are not acceptable for 2” to 48”

pipelines. Fabricated versions typically use four gear actuated resilient

seated butterfly valves although it’s possible to use double/triple offset

butterfly valves or ball valves for flow diversion. If there are special

valve requirements, we will typically provide the strainer bodies and flanged

manifolds, letting the customer procure whatever valves they desire.

Fabricated versions are used for higher-pressure

applications and when cast iron bodies are not acceptable for 2” to 48”

pipelines. Fabricated versions typically use four gear actuated resilient

seated butterfly valves although it’s possible to use double/triple offset

butterfly valves or ball valves for flow diversion. If there are special

valve requirements, we will typically provide the strainer bodies and flanged

manifolds, letting the customer procure whatever valves they desire.

Sliding Valve Design

This design provides yet another way of simultaneously diverting flow between

strainer basket chambers. An advantage of the sliding valve design is that

the valve is completely out of the flow path.

This design provides yet another way of simultaneously diverting flow between

strainer basket chambers. An advantage of the sliding valve design is that

the valve is completely out of the flow path.

Which Duplex Strainer Design is Best?

Often the design criteria of your application will dictate a combination

of characteristics only available in a particular design; if you require a 4”

Inconel duplex strainer, you only have the custom fabricated style to work with.

Likewise a 2” size application for a 316SS duplex strainer will be handled more

economically with a cast valve cartridge design compared to a custom fabricated

one; but what about an 8” water application where cast iron is acceptable and

there’s diverting-plug, butterfly and sliding valve designs to choose from?