Automatic Strainers

Differences between backwashing and mechanically cleaned designs

Automatic strainers and filter

systems support continuous flow rate applications by reducing or

eliminating personnel that would otherwise be required to manually

operate duplex strainers. The styles described below are the most

common types used for industrial applications and after reading this

article you should have a better understanding of which style would work

best for your application.

Flushing Strainers

This type of strainer is a modification of

a standard basket strainer having a drain valve at the bottom of the

element chamber, which can be manually or remotely actuated.

Opening the drain valve causes a "toilet bowl effect" of flushing

retained solids out the drain, thus this works best with non-deformable

solids and for lower solids concentrations. Since the flow is not

reversed through the element, deformable and fibrous solids have a

tendency to remain embedded and will require manual cleaning at some

point. This is a very inexpensive design and typically shipments

can be made within 2 weeks or less.

Backwashing Strainers and Filters

Backwashing Strainers and Filters

Automatic strainers and filter systems are

designed to minimize any interaction with personnel and there are many

benefits. Elimination of physical lifting of heavy (filled)

strainer elements, exposure to cleaning chemicals and the physical

scrubbing itself are all aspects which reduce labor hours required to

keep the system operating continuously.

Automatic systems are generally limited to

particle concentrations of <=200 PPM and require either electricity or

instrument quality compressed air to operate. Compared to duplex

strainers, automatic strainers typically cost the same or less for

pipelines >6".

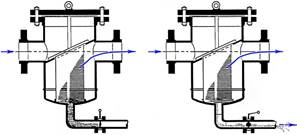

Backwashing refers to the temporary

reversal of flow through one or more filtration elements. During

normal operation, large particles either become stuck against the

element surface or fall to the bottom of the vessel. The particle

size allowed to pass through to the outlet depends upon the opening size

of the element.

Backwashing occurs when a drain valve is

opened such that the differential pressure between atmospheric and the

system pressure causes reversal of flow across the element, dislodging

particles to a common drain. Unlike the aforementioned "flushing

strainer", the reversal of flow through the element is concentrated by

the system design. The Eaton model 2596 illustrated above is

typical for high flow water systems common in power plants, steel mills

and paper mills. These have a hollow nozzle arm, which has the

same length as the element, and this arm slowly rotates across the

surface of the element, amplifying the differential pressure and

reversal of flow effect; the particles are essentially vacuumed off the

element.

Backwashing occurs when a drain valve is

opened such that the differential pressure between atmospheric and the

system pressure causes reversal of flow across the element, dislodging

particles to a common drain. Unlike the aforementioned "flushing

strainer", the reversal of flow through the element is concentrated by

the system design. The Eaton model 2596 illustrated above is

typical for high flow water systems common in power plants, steel mills

and paper mills. These have a hollow nozzle arm, which has the

same length as the element, and this arm slowly rotates across the

surface of the element, amplifying the differential pressure and

reversal of flow effect; the particles are essentially vacuumed off the

element.

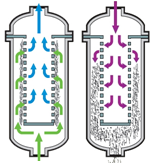

Tubular backwashing designs are made for finer particle

retention and rely solely upon the differential pressure for element

cleaning. The elements are specifically designed to evenly

distribute reversed flow to ensure efficient element cleaning.

Tubular backwashing designs are made for finer particle

retention and rely solely upon the differential pressure for element

cleaning. The elements are specifically designed to evenly

distribute reversed flow to ensure efficient element cleaning.

Backwashing systems are most commonly used

for water applications because the backwashing procedure may require up

to 5% of the system flow for a few minutes each time backwashing occurs.

Therefore, your process needs to tolerate a temporary reduction in flow

or the pump needs to be capable of delivering additional flow during the

backwashing process.

Backwashing strainers function most

efficiently when the system pressure is >30 PSI as that equates to a

differential pressure of about 15 PSI (because you are discharging to

atmospheric pressure).

The backwashing function can be initiated

by timer, differential pressure or manually with the push of a button.

Mechanically Cleaned Elements

As with simplex basket strainers, particulate enters

into a cylindrical, tube shaped element, having no bottom or top.

The bottom end of the vessel is where the drain port is located and thus

large/heavy particles will naturally fall to the drain or purge area of

the vessel. The particles too large to pass through the element

become stuck to the surface and perhaps some are wedged into the

openings.

Cleaning occurs when a spring-loaded disc

traverses the element interior. The disc is comprised of four

sections; spring loading ensures a constant pressure is exerted to the

element surface. The disc material, which is available in UHMWPE,

PTFE and PVDF, pushes the retained particles downwards to the purge

chamber. The user can adjust the frequency of strokes. An

advantage of this style is that frequent strokes help ensure a

consistent differential pressure, minimizing pressure spikes and changes

in flow rate.

The bottom of the vessel, the "purge

chamber", is shaped to increase purging efficiency. An automated

valve opens; the system backpressure pushes the fluid and accumulated

particles through the valve prior to closing. The entire cycle

lasts only a few seconds. The frequency of purging is also user

settable.

Mechanically cleaned systems provide very

efficient performance for applications which have a continuous and

predictable solids loading characteristic.

Loss of process fluid is minimized, making

this design well suited for non-water fluids, which either have value or

are more expensive to dispose. Mechanically cleaned elements are

excellent for viscous fluids such as plastisol.

Designs are available to operate the

stroking either pneumatically or electrically and some designs are

self-contained, meaning there is no penetration through the chamber

cover to actuate the stroke.

Just about any filtration application can

be automated; the design that is best for you depends upon the

requirements of your application. Our training and experience

enables us to gather the right information and guide you to the best

configuration. Additional information describing our automatic

strainers is online at

https://automaticstrainers.com.