Introducing the Hayward TBH Series Ball Valve

System2™ sealing, an evolution of non-alloy ball valve design

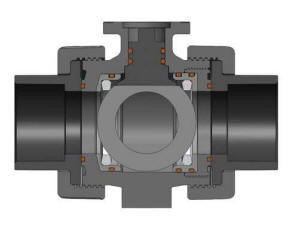

Hayward's new TBH true union ball valve design with System2™

sealing technology is an evolutionary redesign of their TB series ball

valve. This new, thoughtful and patented valve design enhances

usability while solving elusive problems that plague all other non-alloy

valves.

System2™ Sealing Technology

Traditional

ball valves have what is referred to as a "floating" ball design, which

refers to the ball within being sealed between a pair of "seats" made of

Teflon. During the life of the valve the seats may wear due to frequent use

or aggressive media, requiring a physical adjustment to keep the seats

against the ball. One problematic aspect with adjustments is it often

requires a special tool and it directly affects the shaft torque; if the

valve is actuated, it is critical to avoid "over-adjustment" otherwise the

actuator will not function.

Traditional

ball valves have what is referred to as a "floating" ball design, which

refers to the ball within being sealed between a pair of "seats" made of

Teflon. During the life of the valve the seats may wear due to frequent use

or aggressive media, requiring a physical adjustment to keep the seats

against the ball. One problematic aspect with adjustments is it often

requires a special tool and it directly affects the shaft torque; if the

valve is actuated, it is critical to avoid "over-adjustment" otherwise the

actuator will not function.

The TBH series ball valve also incorporates a

"free

floating" ball design; however the patented System2™ seat carrier will never

require adjustment. The seat design for the TBH series enables the upstream

seat to slide against the ball, forming a backup, secondary auto-adjusting

seat seal. The primary benefit of this design is that the actuation

torque is maintained throughout the valve's life, eliminating manual labor

associated with seat adjustments for old-fashioned style valves.

Safety

Locking-out valve actuation is an important safety procedure to avoid accidental operation during maintenance or to prevent interruption of critical processes. Unlike many valves which rely on "clamshell-like" enclosures to prevent actuation, the new TBH series design enables up to four locks to be installed simultaneously. Each of the padlock shackles (shanks) physically prevents valve actuation. Thus, for no additional cost, up to four lock-outs can be accommodated.

Versatility

The new TBH series valve body has an ISO 5211

mounting pad, thus if you would like to use your own actuator all you

require is a shaft coupling (9, 11 or 14mm) as any actuator having an ISO

5211 mount will connect directly to the valve, eliminating adapter kits

required for older valve designs.

The TBH series also has an integral foot pad with

hex shaped nut holders for panel mounting and permanent markings in lieu of

outdated labels with the part number, size and QR code to instantly link you

to its IOM manual.

Ergonomics

Ergonomics

Perhaps an overlooked aspect of ball valve

designs, the handle of the TBH series improves usability with an easier

grip for either your right or left hand. You will notice the valve

handle curves slightly upwards which enables smaller hands to grip the

handle better while raising your fingers a bit above the valve body to

avoid "knuckle-busting" contact. Hand slippage is also less of a factor

in wet conditions.

Summary

The TBH series true union ball valve with

System2™ sealing design is fully bi-directional and offered in PVC and

CPVC materials with a choice of either EPDM or FPM seals. In addition to

two-way ball valves, the Profile2™ proportional flow control valves and

"Z-Ball" sodium hypochlorite valves also utilize the new System2™

sealing seat design; having all the features described.

Hayward took what was already a fantastic

ball valve design and made it even better by listening to our customer's

feedback regarding desirable features and improvements. The

resulting TBH series valve represents an evolution in non-alloy ball

valve design.