Filtration Efficiency

Understanding Retention Efficiencies for Filter Cartridges

Selecting

the proper filter cartridge retention for a given application reduces operating costs and ensures process specifications are achieved.

Filter cartridge retention is expressed in microns (μm); 1 micron =

1/1000 (0.001) millimeters.

Selecting

the proper filter cartridge retention for a given application reduces operating costs and ensures process specifications are achieved.

Filter cartridge retention is expressed in microns (μm); 1 micron =

1/1000 (0.001) millimeters.

Nominal Efficiency is a manufacturer

defined efficiency and for our nominal rated filter cartridges they are

70% efficient unless otherwise specified. Therefore, with a new

(clean) filter cartridge,

=>70% of the particles of the stated retention

will be retained by the filter cartridge. As particles become trapped

within the filter cartridge media, the open area available decreases and

thereby increases the efficiency of the filter cartridge.

As mentioned above, there is no

"universal" retention efficiency required to be referred to as "nominal"

- it is manufacturer defined, often not overtly stated; you will need

to ask if your application is one of those sensitive to the initial

retention efficiency.

Therefore it is incorrect to assume that

two different brands of "50 micron nominally rated filter cartridges"

have the same efficiency; you will need to try each to determine which

is the best value for your application. Generally speaking the

more efficient the media is, the more costly it is because the

manufacturers of the filter media can get top dollar for the more

efficient portion of the media run.

In comparison to absolute rated filter

media, nominal rated filter cartridges are relatively inexpensive and

used for non-critical applications. They are also used as

"pre-filters" to reduce the loading on the more expensive "absolute"

efficiency filter cartridges.

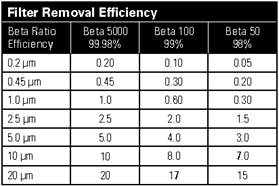

Absolute Efficiency is much more

intuitive and straightforward to understand. It refers to a

laboratory defined retention efficiency, often expressed with a

Beta

value or a Beta Ratio. Most of our

absolute rated filter cartridges have a Beta

Ratio Chart expressing their efficiency based upon a stated particle

size.

Example:

our LOFPLEAT-HP 1.0 micron filter cartridges have a Beta 5000 or

99.98% retention efficiency for particles => 1.0 micron. They can

also be described as Beta 100 (99%) efficient for retention of particles

=> 0.60 microns or Beta 50 (98%) efficient for retention of particles =>

0.30 microns.

Example:

our LOFPLEAT-HP 1.0 micron filter cartridges have a Beta 5000 or

99.98% retention efficiency for particles => 1.0 micron. They can

also be described as Beta 100 (99%) efficient for retention of particles

=> 0.60 microns or Beta 50 (98%) efficient for retention of particles =>

0.30 microns.

The Beta Ratio is established via

laboratory testing and is the number of particles up-steam of the

cartridge divided by the number of particles downstream of that same

cartridge for the targeted particle size.

Therefore a Beta ratio of 5000 means that for every

particle of a given size that bypasses the filter cartridge, there were

4999 that did not. The math follows:

![]() Beta

5000 = 4999 particles retained from a total of 5000 and therefore 4999/5000 = 99.98%

efficiency.

Beta

5000 = 4999 particles retained from a total of 5000 and therefore 4999/5000 = 99.98%

efficiency.

The testing methods used to determine

efficiency can be complex and they are not to a universal standard; each

manufacturer determines how they will test their efficiencies.

The testing method used for Eaton's Beta

Ratios are based upon a "single-pass test method" using ambient water at

a flow rate of 2.5 GPM for a 10" length cartridge. The type of

particles used during testing are latex beads and special "coarse and

fine test dust" (imagine that, "test dust"!). The removal efficiencies

are determined using multiple laser particle counters which is the most

sophisticated and effective method of counting "dust" particles.

The

actual efficiency for your application will differ due to operating

conditions such as pressure fluctuations, differences in temperature and

viscosity. This is another reason why trying different filter

cartridge brands, media and designs can be beneficial to you, your

process results will not likely correlate directly to "retention sizes

or efficiencies" due to process variations anyway.

It is important not to confuse filtration

efficiency with particle retention capacity; they are unrelated.

The total volume of particles that can be retained within a cartridge

and how the rate of increase in efficiency due to reduction of the open

area available are not reflected in the Beta Ratio and testing.

Underscoring once again that the physical design of the filter cartridge

may offer capacity advantages even if the media used is the same across

multiple brands/designs.

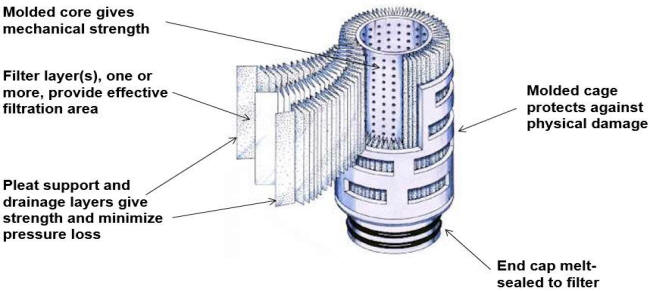

Our

differential performance advantage compared to other brands are often

based upon the manufacturing technology and design of the filter

cartridge to provide higher volume of particle retention at relatively

low differential pressures without sacrificing retention efficiency.

The picture above illustrates a pleated design, although other advanced

features can include a fixed pore structure that prevents particle

unloading even under high differential pressures or a heavy molded

"cage" to increase the overall integrity/strength of the filter

cartridge.

Do you require nominal or absolute rated

filter cartridges?

If you have sensitive applications

requiring absolute rated media, you probably already know it and have an

application that involves the food, beverage, pharmaceutical, cosmetics

or petrochemical industries. It is important to note that the

lesser expensive nominal rated cartridges can be used to extend the life

of the much more expensive absolute rated cartridges, so the answer

might be "both"!

We can provide you with free filter

cartridges for testing and evaluation combined with free water test

analysis/report which will characterize the particle sizes and

population within a given sample that you provide. The analysis

eliminates "trial and error" for proper filter cartridge material and

design. Why not take advantage of these free services today?