Characteristics of Industrial Peristaltic Pumps

Peristaltic hose pump design

The

peristaltic pump was patented in 1881 by Eugene Allen to be used for blood

transfusions and, although modern industrial peristaltic pumps are much more

efficient and compact than Mr. Allen's patented design, the basic principle

of operation remains the same.

The

peristaltic pump was patented in 1881 by Eugene Allen to be used for blood

transfusions and, although modern industrial peristaltic pumps are much more

efficient and compact than Mr. Allen's patented design, the basic principle

of operation remains the same.

How Peristaltic Pumps Work

The flow rate is

somewhat proportional to the rotational speed with a key variable being the

amount of hose compression. While laboratory size peristaltic pumps

utilize non-reinforced tubing and completely "pinch" the tube to provide

accurate dosing, industrial size peristaltic pumps are not typically

operated in that fashion because the hoses are more rigid and would require

replacement frequently if they were compressed completely.

Therefore, an

industrial peristaltic pump always has some "slip", especially if the

discharge pressure is higher and the fluid has a water-like viscosity.

Thus higher viscosity fluids can be pumped at higher pressures than lower

viscosity fluids when the hose isn't pinched closed 100%.

Peristaltic Pump Hose Design

A peristaltic pump hose needs replacement when the dosed volume decreases to an unacceptable level, which is a reflection of the hose remaining somewhat elliptical shaped even when not being compressed. This "hose fatigue" can eventually result in cracking or delamination of the internal layer if it is a lined hose design. It is preferable to replace a hose before it completely fails, to prevent the process fluid from leaking into and potentially out of the pump.

t is a little known

"industry secret" that most peristaltic pump manufacturers use the same few

hose manufacturers and this is because the hose design is especially

complex. The hoses we provide for our Vector series of peristaltic

pumps will also work in Verderflex® and Watson-Marlow Bredel™

pumps.

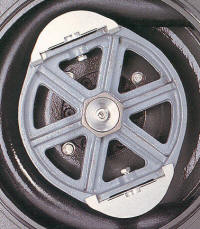

Roller and Shoe Design

Roller and Shoe Design

Shoe designs are capable of higher pressures and therefore the decision for which design is best for a given application is usually both pressure and application based.

Roller designs only

require a light coating of silicon grease on the hose surface because the

roller "rolls" across the hose surface. Therefore applications

involving food and beverages might benefit from this design as the potential

for cross contamination if a hose fails is less than shoe design pumps

bathed in a lubrication oil - even if that oil is "food grade", it is still

often preferable to go with a roller design.

If

the pressures are not high, the roller design should provide longer hose

life and overall be a more cost effective solution.

If

the pressures are not high, the roller design should provide longer hose

life and overall be a more cost effective solution.

Peristaltic pumps

also do not have internal check valves to control the direction of flow and

therefore can handle relatively large solids and fibrous (long) solids,

which would cause havoc in pumps such as air operated diaphragm pumps that

utilize ball-check valves to control the flow direction.

Since there are no

moving, sliding or rotating components dependent upon the fluid being pumped

for lubrication or cooling, peristaltic pumps can operate dry and are often

used to "suck dry" tanks and totes.

Peristaltic pump

hoses can be replaced with minimal effort - the design of a peristaltic pump

is rather simplistic from a user's perspective, so it is easy to replace a

hose and to know when a hose requires replacement. There are no other

parts to replace!

The pump shaft speed

is achieved via a gearbox or gear-motor, because using a mechanical speed

reduction with a standard 1800 RPM motor reduces the motor size (HP)

required. Once a gearbox/motor is selected, the maximum shaft speed is

fixed and you can use an optional VFD to further reduce the shaft speed if

desired.

The amount of

compression applied to the peristaltic hose is adjustable by installing

shims under the roller or shoe mounts. The initial set-up procedure

involves installing shims until the desired flow is achieved, thus

compressing the hose minimally.

If you have

peristaltic pumps, talk to us about your application and pump model and we

will help ensure you are using the best hose design and at a competitive

cost.

Advantages of Peristaltic Pumps

Proper Sizing of Peristaltic Pumps